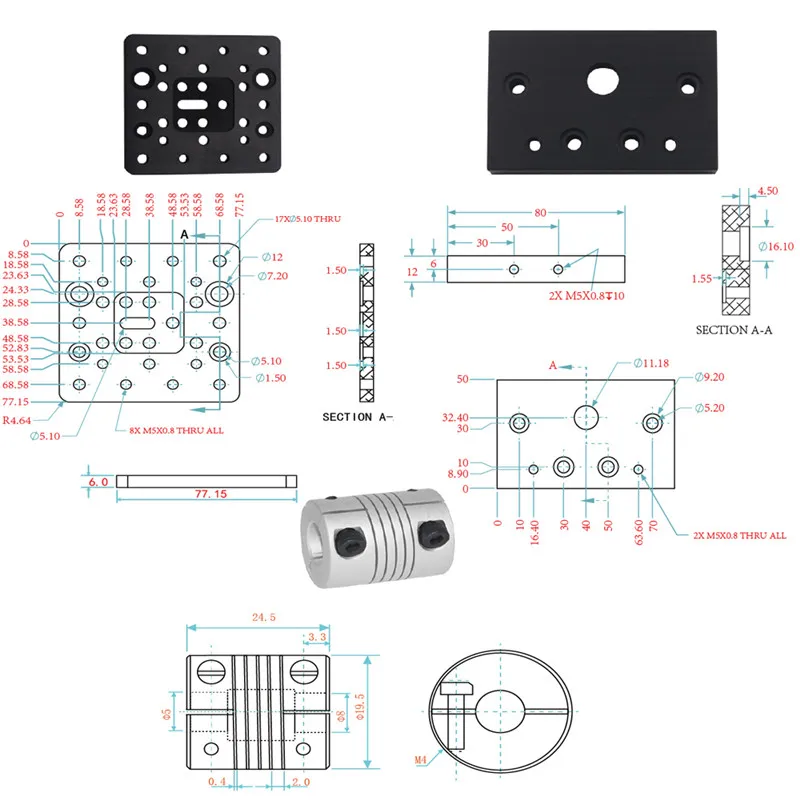

T8 Lead Screw Specifications

Model: T8 sliding table

Product specifications: 200mm (with silver aluminum), 200mm (with black aluminum)

Accuracy: 0.001 ~ 0.003" (0.05 mm ~ 0.10 mm)

Accurate positioning: 0.091 mm

Maximum force: 26 lbs (115 n)

Maximum speed: 8000 mm/min

T8 Lead Screw Specifications: High Precision and Versatility for Your Projects

The T8 lead screw is a widely used component in mechanical and engineering applications, specifically for linear motion systems. Known for its precision, durability, and reliability, the T8 lead screw plays a crucial role in the movement and positioning of machinery. It’s commonly used in 3D printers, CNC machines, robotics, and other equipment that requires smooth, accurate motion.

The T8 lead screw features a trapezoidal thread profile, designed to provide high efficiency and minimal backlash, making it an ideal choice for precise movements and linear actuation. Whether you're designing or maintaining mechanical systems, understanding the T8 lead screw’s specifications is crucial for selecting the right component for your application.

Key Specifications of T8 Lead Screw

-

Lead Size: The “T8” designation refers to the lead size of the screw, which is 8mm. This means the nut moves 8mm for each

full rotation of the screw. The lead size determines how much distance the nut will travel for each rotation of the lead screw.

-

Thread Pitch: The T8 lead screw has a pitch of 2mm, meaning the distance between threads is 2mm. This fine pitch provides

high precision, making it ideal for applications requiring smooth, controlled movements.

-

Diameter: The nominal diameter of the T8 lead screw is 8mm. This measurement is crucial for compatibility with nuts,

bearings, and other components designed for T8 screws.

-

Thread Type: The T8 lead screw uses a trapezoidal thread profile, commonly referred to as an “ACME thread.” This thread

design helps minimize backlash and provides efficient power transmission in linear motion systems.

-

Material: T8 lead screws are typically made from high-quality stainless steel, carbon steel, or alloy steel. The material

choice affects the screw's durability, corrosion resistance, and load-bearing capacity.

-

Nut Compatibility: T8 lead screws are compatible with T8 nuts, which have matching threads and a smooth sliding surface.

These nuts are available in different materials such as brass, stainless steel, or plastic, depending on the application.

-

Length Options: T8 lead screws come in various lengths, typically ranging from a few inches to several feet, to accommodate

different system sizes and application requirements.

-

Backlash: One of the key advantages of T8 lead screws is their low backlash. However, the amount of backlash can vary

depending on the manufacturing quality, nut fit, and lubrication. Reduced backlash enhances precision and accuracy in motion control.

-

Efficiency: The efficiency of T8 lead screws generally ranges from 30% to 50%, depending on the lead angle, material, and

lubrication. T8 screws offer moderate efficiency compared to other types like ball screws, but they are more cost-effective and simpler in

design.

Applications of T8 Lead Screws

T8 lead screws are widely used in applications requiring precise linear motion, including:

-

3D Printers: The T8 lead screw is commonly used in 3D printers for controlling the movement of the print head or bed,

providing smooth, accurate positioning.

- CNC Machines: T8 lead screws are used in CNC systems for precise positioning of tools or workpieces.

- Robotics: T8 lead screws are used in robotic actuators and systems that require controlled linear motion.

-

Linear Actuators: The T8 lead screw is often used in various linear actuation systems where the translation of rotational

motion to linear motion is required.

-

Medical Equipment: Some medical devices utilize T8 lead screws for precise movement in mechanical systems such as

examination tables, patient beds, and robotic surgery tools.

Advantages of T8 Lead Screws

-

High Precision: T8 lead screws provide excellent accuracy for linear motion, making them ideal for applications where small

adjustments and precise control are required.

-

Low Backlash: The trapezoidal thread profile of the T8 lead screw reduces backlash, resulting in smoother and more accurate

movement.

-

Durability: Made from durable materials such as stainless steel or carbon steel, T8 lead screws offer long-lasting

performance, even in demanding environments.

-

Cost-Effective: Compared to other linear motion components like ball screws, T8 lead screws are relatively affordable,

making them a great option for budget-conscious projects.

-

Versatility: T8 lead screws are available in various lengths, diameters, and materials, allowing them to be used in a wide

range of applications.

Conclusion: Choosing the Right T8 Lead Screw for Your Application

T8 lead screws are a reliable and cost-effective solution for a wide range of mechanical and engineering applications. Their precise movement, low backlash, and durable construction make them ideal for tasks that require smooth and accurate linear motion. Whether you're working on a 3D printer, CNC machine, or robotics system, the T8 lead screw is a valuable component to consider for your project.

Understanding the key specifications of T8 lead screws, such as lead size, pitch, and material, will help you choose the right screw for your specific needs, ensuring efficient and reliable performance.

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

Shop amazing plants at The Node – a top destination for plant lovers

.png)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

ulva-Logo.jpg)

.jpeg)

.png)

.png)