Soldering Iron Flux

Product information :

Model: US 110V, European 220V, UK +3 yuan, Australia +3 yuan

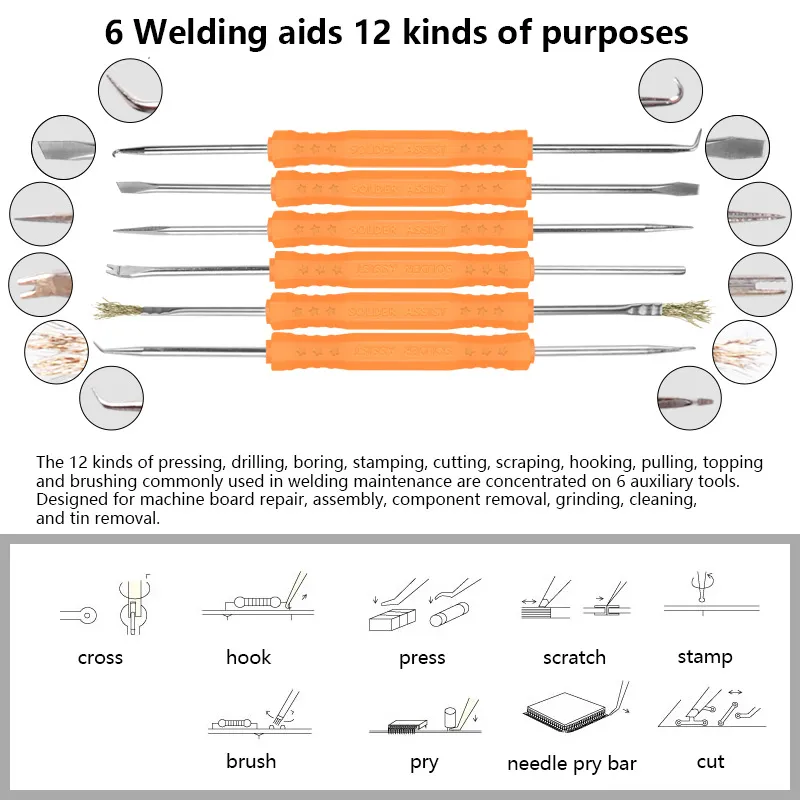

Item No. : Flux Tool Set

Material: plastic handle electric soldering iron

Number of Phases : 2

Input voltage: 110/220 (V)

Power: 60 (W)

Voltage adjustment range: 110-220 (V)

Current : AC

Temperature range: 200-450 (℃)

Tip and ground impedance: 2 (Ω)

Tip and ground voltage: 2 (mV)

Standard soldering iron tip: 900M

Soldering iron tip temperature: 450 (℃)

Drive form: electric heating

Power form: electric heat

Protection class: excellent

Dimensions: 22CM

Uses: Soldering, electrical welding maintenance

Shell protection grade: excellent

Specifications: US, EU, UK, Australia

Packing list:

Flux tool set*1

Soldering Iron Flux – Essential for Smooth, High-Quality Soldering Connections

Product Description

H1: Soldering Iron Flux – Achieve Strong and Clean Solder Joints for Professional Results

The Soldering Iron Flux is an essential tool for any soldering project, helping to create strong, reliable, and clean joints. Whether you're working on electronics, DIY projects, or jewelry making, flux enhances the flow of solder and ensures smooth, efficient connections between components. With the right flux, you can prevent oxidation, reduce the risk of cold solder joints, and improve the overall performance of your soldering work.

Designed to make your soldering process easier and more effective, Soldering Iron Flux is a must-have for professionals and hobbyists alike.

H2: What is Soldering Iron Flux and Why Is It Important?

Soldering Iron Flux is a chemical agent used in the process of soldering to clean and prepare surfaces for the solder to bond properly. It helps to remove oxidation from the metals being soldered, promoting better heat transfer and preventing the formation of weak, unreliable solder joints. Flux improves the flow of the molten solder, ensuring that it adheres properly and creates a strong, solid connection between the components.

Without flux, solder may not flow as smoothly, leading to weak, cold joints that could fail over time. Flux also helps reduce the likelihood of solder splashes or spattering during the heating process, providing a cleaner workspace and a more polished final product.

H2: Types of Soldering Iron Flux for Different Projects

There are various types of Soldering Iron Flux, each suited for specific types of projects. Choosing the right flux for your work ensures that you achieve the best results and maintain the integrity of your work. Here are the common types of flux:

-

Rosin Flux: The most common type of flux, used in general-purpose soldering applications. It comes in both liquid and paste

forms and is ideal for electronic projects, including circuit board soldering.

-

Water-Soluble Flux: This type of flux is more aggressive in cleaning the surfaces to be soldered, making it a good choice

for precision work. However, it must be cleaned thoroughly after soldering, as it is more prone to leaving residues.

-

No-Clean Flux: Designed for use in situations where it’s difficult to clean flux residues. It leaves minimal residue that

doesn't require cleaning and is ideal for surface-mounted devices (SMD) and compact electronics.

-

Acid Flux: Typically used for plumbing and metalworking applications, acid flux is more corrosive and should be used

carefully. It’s perfect for projects requiring high heat, like large electrical components or metal pipes.

Choosing the right flux for your project will help you achieve better soldering results, prevent oxidation, and minimize the chances of defects.

H2: Key Benefits of Using Soldering Iron Flux

The benefits of using Soldering Iron Flux in your projects are numerous, especially when working with delicate electronics or heavy-duty projects that require strong joints. Here’s why flux is essential for successful soldering:

-

Promotes Stronger Joints: Flux ensures that the solder flows evenly and bonds well with the metal, creating strong, durable

connections.

-

Prevents Oxidation: Flux removes impurities and oxidation from the metals being soldered, improving the solder’s ability to

adhere to the surface.

-

Reduces Soldering Defects: By improving the flow of solder, flux reduces the risk of cold joints, which can cause

malfunction or failure in your project.

-

Improves Heat Transfer: Flux helps to maintain an even distribution of heat, preventing overheating of components and

ensuring the best results.

-

Cleaner Soldering: Flux reduces spattering and solder splashes, leading to a cleaner work environment and smoother, more

professional-looking joints.

With flux, your soldering projects will be faster, more efficient, and produce higher-quality results.

H2: Easy to Use and Apply for Precision Soldering

Using Soldering Iron Flux is straightforward, and with the right technique, you can achieve precise, clean, and strong solder joints. Flux comes in a variety of forms, including liquid, paste, or gel, and can be easily applied to the joint area using a brush, syringe, or even a pen applicator for precision work.

For the best results, follow these steps:

-

Apply Flux: Use the flux applicator to apply a small amount of flux to the metal surfaces that you plan to solder. Be sure

to coat both the pad and the lead or wire.

-

Heat the Soldering Iron: Preheat your soldering iron to the desired temperature. Ensure that the tip of the soldering iron

is clean and free from old flux residue.

-

Solder the Joint: Once the flux is applied, position the soldering iron tip on the joint, allowing the heat to activate the

flux. Then, feed the solder onto the joint, allowing it to flow evenly over the surface.

-

Clean After Soldering: After the solder has cooled, clean off any remaining flux residue with a suitable cleaning solution,

depending on the type of flux used (e.g., alcohol or water for rosin flux).

Using flux correctly ensures that your soldering work is neat, efficient, and produces high-quality results.

H2: Versatile for Various Soldering Applications

Soldering Iron Flux is suitable for a wide range of applications. It is essential for:

-

Electronics: Used to ensure strong, conductive, and long-lasting connections for circuit boards, resistors, capacitors, and

other components.

-

Plumbing: In plumbing, flux is used to create a strong seal between metal pipes and fittings, preventing leaks.

-

Jewelry Making: For those working in metal arts or jewelry making, flux is critical to achieving precise, clean metal

joints and soldering intricate pieces.

-

Automotive and Electrical Work: Flux is used in automotive wiring and other electrical projects to ensure secure, reliable

connections.

Whether you are soldering delicate electronics or working on larger metal projects, flux is an essential tool to ensure smooth, strong, and clean results.

H2: Safe Handling and Storage Tips for Soldering Iron Flux

While Soldering Iron Flux is generally safe to use, it's important to handle it with care and store it properly to ensure both safety and effectiveness.

-

Use in a Well-Ventilated Area: Some types of flux emit fumes when heated. Always work in a well-ventilated area or use a

fume extractor to avoid inhaling harmful fumes.

-

Avoid Contact with Skin: Flux can irritate the skin, so it’s important to wear gloves when handling it. Always wash your

hands thoroughly after use.

-

Proper Storage: Keep flux in its original container and store it in a cool, dry place away from direct sunlight or heat

sources. This will help maintain its effectiveness for longer periods.

By following safety guidelines and handling flux properly, you can ensure a safe and effective soldering process.

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

Shop amazing plants at The Node – a top destination for plant lovers

.png)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

ulva-Logo.jpg)

.jpeg)

.png)

.png)