Pneumatic Rivet Gun

Model sandblasting gun, buy a spare gun

Classification upper pot type sandblasting gun

Color: 1

Tank capacity 21Ibs (ml)

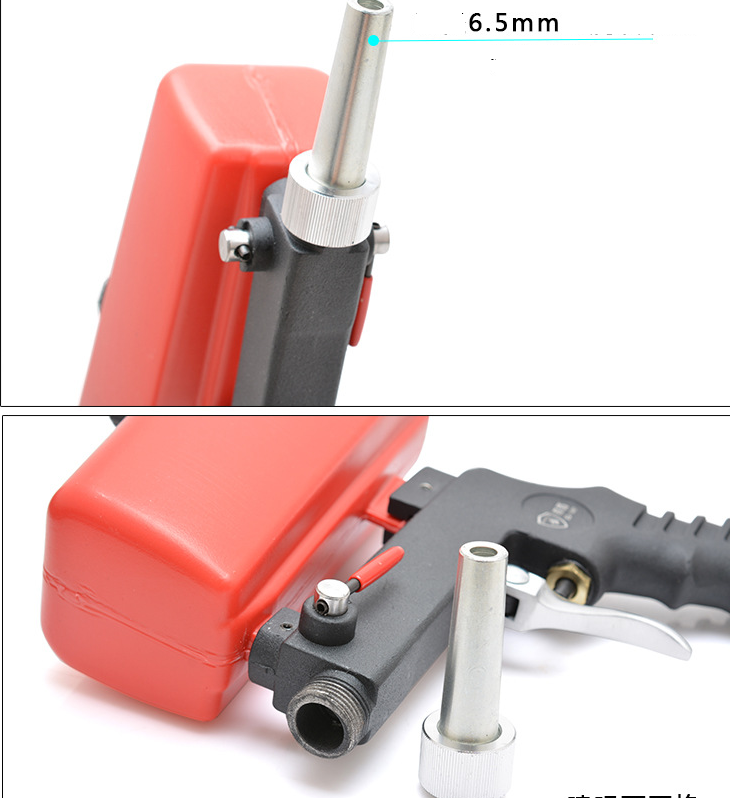

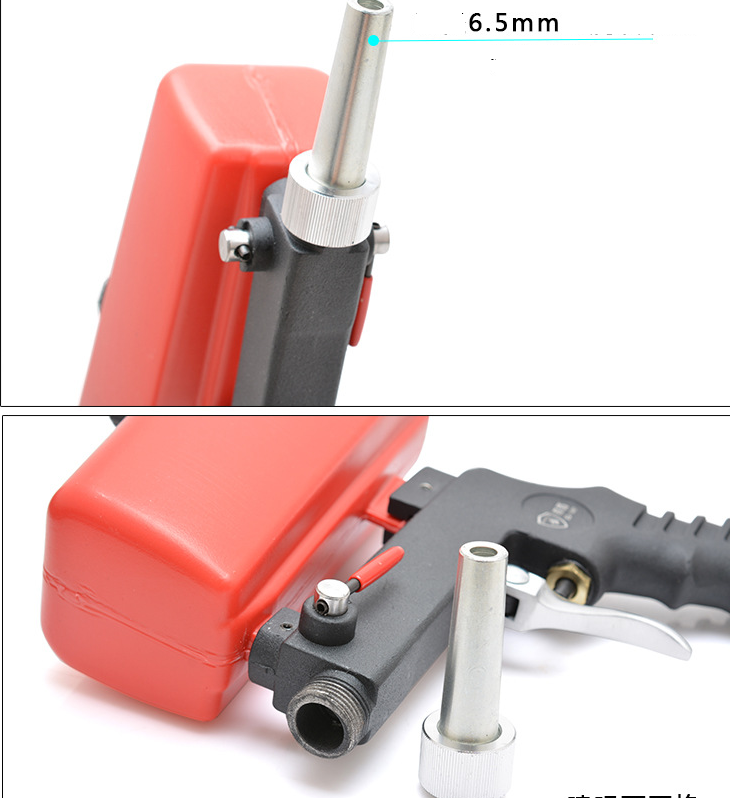

Spray hole diameter 6.5mm (mm)

Working pressure 90PSI (Mpa)

Tool net weight 0.73 (kg)

Series Pneumatic Sandblasting Gun

Please do not use your hands to test the sandblasting gun.

Please wear protective measures (protective glasses / masks, etc.) at working.

It can be used for descaling, residue, rust removal, core renovation, atomization, deburring, welding, etc.

Pneumatic Rivet Gun – Industrial-Grade Air Riveter for Sandblasting Systems

Perfect for sandblasting professionals, metal fabricators, industrial maintenance teams, and engineering workshops across New Zealand who require a durable, high-pressure pneumatic rivet gun for assembling, repairing, or reinforcing sandblasting equipment and protective systems.

In the demanding world of sandblasting—where reliability, safety, and precision matter most—the Pneumatic Rivet Gun provides powerful and consistent fastening performance. It’s built to handle the harsh conditions of abrasive blasting environments, where equipment faces constant vibration, dust, and heavy use. Designed for use in sandblast pot assembly, steel frame reinforcement, nozzle housing installation, and blast cabinet maintenance, this rivet gun ensures tight, secure connections that withstand high pressures and repeated stress.

Whether you’re maintaining a portable blast pot in Auckland, assembling heavy steel frames in Christchurch, or servicing marine blasting gear in Tauranga, this pneumatic riveter delivers unmatched strength, speed, and endurance.

Description – Pneumatic Rivet Gun for Sandblasting

The Pneumatic Rivet Gun for Sandblasting is a professional-grade air-powered fastening tool engineered specifically for environments where durability and reliability are essential. In sandblasting systems, every joint, clamp, and support must endure vibration, pressure, and continuous movement—this rivet gun is built for exactly that.

Made with hardened alloy steel internals and a corrosion-resistant anodised aluminium body, it performs flawlessly even in abrasive or dusty conditions. It uses compressed air—typically between 4 to 8 bar—to generate a strong pulling force that sets blind rivets instantly, producing tight, vibration-proof joints.

The precision-engineered air motor converts air pressure into linear pulling motion, forming uniform rivet heads without damaging surrounding components. The dual-action trigger system provides both power and control, allowing the operator to adjust pulling speed and stroke length for different material thicknesses commonly found in sandblasting frames, tanks, and equipment housings.

Each unit includes multiple interchangeable nosepieces to fit various rivet diameters (2.4mm–6.4mm). The quick-release mandrel collector keeps workspaces clean—critical in abrasive environments—and prevents stray mandrels from contaminating blasting media.

The tool’s ergonomic grip and balanced body design ensure operator comfort during long use, especially when assembling blast cabinets, nozzles, frames, or compressor housing units. With low vibration and an insulated handle, it minimises fatigue and offers full control, even during continuous use in high-decibel workshop environments.

This rivet gun is fully compatible with compressed-air systems commonly found in sandblasting setups and maintenance facilities across New Zealand. Its efficient air consumption and robust sealing system make it suitable for field and shop use alike.

Key Points

Built for Sandblasting Environments:

Specifically designed to perform under dust, vibration, and abrasive conditions found in sandblasting operations. The sealed body prevents

grit ingress and prolongs tool life.

Heavy-Duty Pneumatic Power:

Uses compressed air to deliver consistent pulling force for fast, secure rivet installation on metal frames, cabinets, pressure tanks, and

compressor housings.

Corrosion & Abrasion Resistant Housing:

Anodised aluminium and hardened steel internals resist wear from fine blasting dust, ensuring reliability even in harsh coastal or

industrial settings.

Interchangeable Nosepieces:

Supports a wide range of rivet sizes, enabling one tool to cover multiple sandblasting equipment types—from small nozzle brackets to

thick-gauge steel chassis.

Quick Mandrel Collection System:

Integrated mandrel container prevents loose metal fragments from entering the blasting workspace, maintaining safety and cleanliness.

Ergonomic Design & Reduced Vibration:

Comfort-grip handle, balanced centre of gravity, and anti-vibration body reduce user fatigue, essential for long assembly or repair

sessions.

Optimised for Workshop Air Systems:

Operates on standard NZ shop compressors (4–8 bar range) with adjustable air regulation, making it a seamless addition to existing

sandblasting setups.

Precision, Speed & Consistency:

Delivers perfectly uniform rivets, ensuring equipment remains airtight, vibration-resistant, and structurally sound under blasting

pressures.

Benefits

Reliable Joints Under Extreme Conditions:

In sandblasting operations, joints face constant shock and vibration. The Pneumatic Rivet Gun creates tight, vibration-resistant connections

that maintain strength through extended use.

Increased Productivity:

By automating the pulling force with compressed air, workers can install hundreds of rivets quickly and consistently—ideal for large blast

cabinet assemblies or repair jobs.

Low Maintenance & Long Life:

Its sealed design keeps abrasive dust out of the air motor, reducing maintenance frequency. Simple oiling through the air inlet keeps it

running smoothly for years.

Safer Work Environment:

The mandrel catcher reduces airborne metal debris, while the low-noise exhaust system ensures a quieter workshop—important for health and

safety compliance.

Enhanced Operator Comfort:

With low vibration, balanced weight, and a non-slip handle, users experience less strain during long assembly or repair sessions.

Universal Application:

Beyond sandblasting, the same gun can be used for repairing compressor frames, tanks, bodywork, and industrial equipment—making it a

versatile investment.

Precision Control:

Adjustable stroke control prevents over-pulling rivets or damaging thin panels, ensuring every fastener is seated perfectly the first time.

Durable in Harsh Environments:

Its construction withstands exposure to grit, humidity, and metal dust. Even in coastal or outdoor blasting sites, corrosion resistance

ensures dependable operation.

Why Choose This Pneumatic Rivet Gun for Sandblasting?

When your work depends on air-driven systems, it makes sense to use tools designed to thrive in the same environment. The Pneumatic Rivet Gun for Sandblasting integrates perfectly into any blasting or surface-preparation workshop.

Unlike manual or electric riveters, this tool’s pneumatic drive is powered by the same compressor system used in blasting pots, pressure regulators, and air dryers—creating efficiency and convenience.

Where sandblasting demands rugged equipment, this gun delivers exceptional performance. It handles abrasive conditions, moisture, and vibration without losing torque or air pressure. Each rivet set is identical, ensuring sealed joints and a professional finish on cabinets, tanks, frames, and covers.

The ergonomic design and reduced noise output make it comfortable for daily use. Operators working on blast pot repairs or assembly lines will appreciate the balanced weight and consistent response. And with replaceable nosepieces, quick cleaning access, and universal airline compatibility, it’s built for the realities of industrial workshops across New Zealand.

If you work in abrasive blasting, marine coating, fabrication, or heavy equipment maintenance, this pneumatic rivet gun is a tool you can rely on day after day. It’s not just durable—it’s engineered for the toughest environments where precision meets performance.

Applications in Sandblasting Operations

Blast Pot Assembly:

Secures panels, support brackets, and reinforcement rings on pressurised blasting tanks.

Cabinet & Enclosure Manufacturing:

Used to rivet steel and aluminium panels in enclosed sandblasting cabinets or booths.

Compressor Frame Fabrication:

Attaches guards, panels, and compressor base frames with consistent pressure-resistant joints.

Nozzle and Hose Bracket Installation:

Creates secure fittings for high-pressure hose holders, nozzle mounts, and control assemblies.

Protective Cage & Frame Reinforcement:

Reinforces the steel frames supporting large blast pots or mobile blasting units.

Marine & Industrial Equipment Maintenance:

Ideal for rivet replacement or repair on corroded structures exposed to moisture and salt air.

Dust Extraction & Ventilation Systems:

Joins sheet-metal ducts, filters, and housing panels in sandblasting ventilation systems.

Workshop Repairs & Retrofits:

Perfect for modifying or refurbishing older blast cabinets, replacing welds with riveted joins that minimise heat distortion.

Technical Performance Overview

- Operating Pressure: 4–8 bar (60–120 psi)

- Rivet Diameter Range: 2.4–6.4 mm (depending on model)

- Air Consumption: Approx. 1–4 L per cycle

- Pulling Force: Up to 10,000 N

- Stroke Length: Adjustable for different rivet materials

- Noise Level: ≤ 80 dB with muffled exhaust

- Housing Material: Anodised aluminium and steel alloy

- Weight: Approx. 1.5–2.2 kg for balance and control

Maintenance & Safety

Lubrication:

Apply 2–3 drops of pneumatic oil into the air inlet before or after each shift to prevent internal corrosion.

Air Supply Quality:

Use clean, dry, filtered air; avoid moisture that could degrade seals or rust internal parts.

PPE Requirements:

Wear eye protection and gloves when riveting near abrasive blasting areas to guard against debris.

Inspection:

Check seals, nosepieces, and mandrel collectors regularly for wear. Replace immediately if damaged.

Storage:

After use, disconnect the air supply and store the rivet gun in a dust-free, dry environment.

Conclusion

The Pneumatic Rivet Gun for Sandblasting is a heavy-duty, professional-grade tool built to perform in the toughest industrial environments New Zealand has to offer. Designed to withstand dust, vibration, and continuous operation, it’s the perfect companion for assembling and maintaining sandblasting systems, compressor housings, and industrial enclosures.

Its powerful air-driven mechanism, ergonomic handling, and noise-reducing design deliver reliable performance shift after shift. Whether you’re maintaining equipment, fabricating steel frames, or building new sandblasting cabinets, this tool ensures every rivet is secure, precise, and built to last.

For Kiwi tradespeople who value craftsmanship, safety, and efficiency, the Pneumatic Rivet Gun for Sandblasting is more than just a tool—it’s an investment in long-term productivity. Built strong, engineered smart, and ready for any challenge, it’s your go-to fastening solution for the abrasive blasting industry.

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

Shop amazing plants at The Node – a top destination for plant lovers

.png)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

ulva-Logo.jpg)

.jpeg)

.png)

.png)