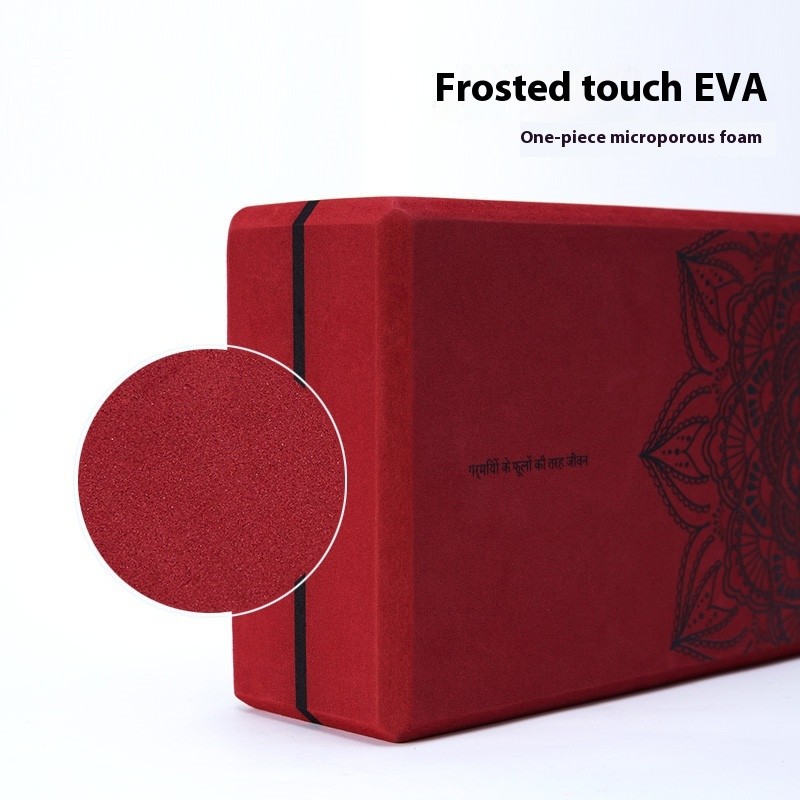

High Density EVA Foam

Product information:

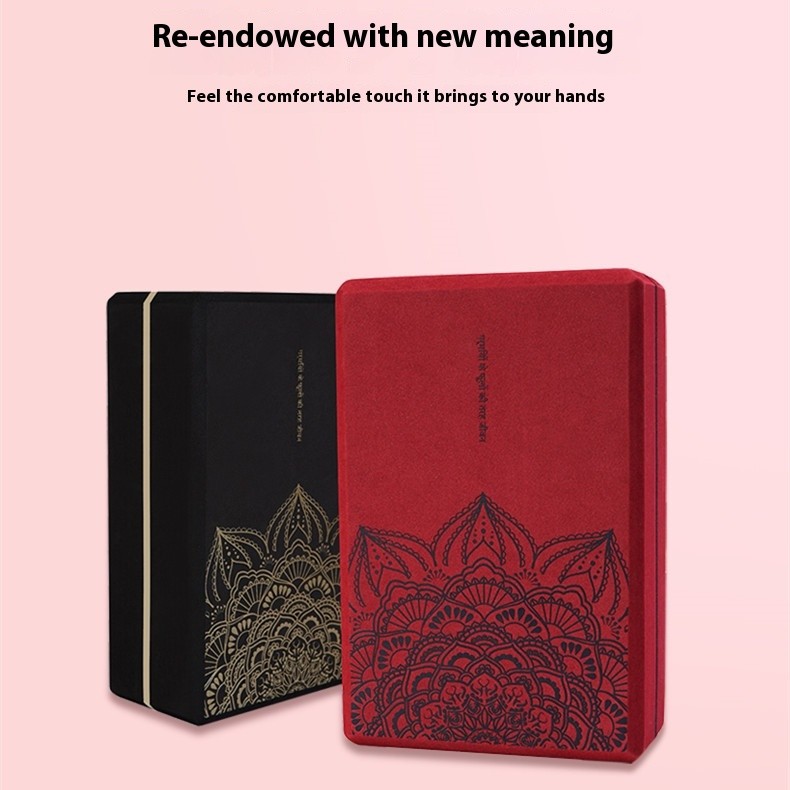

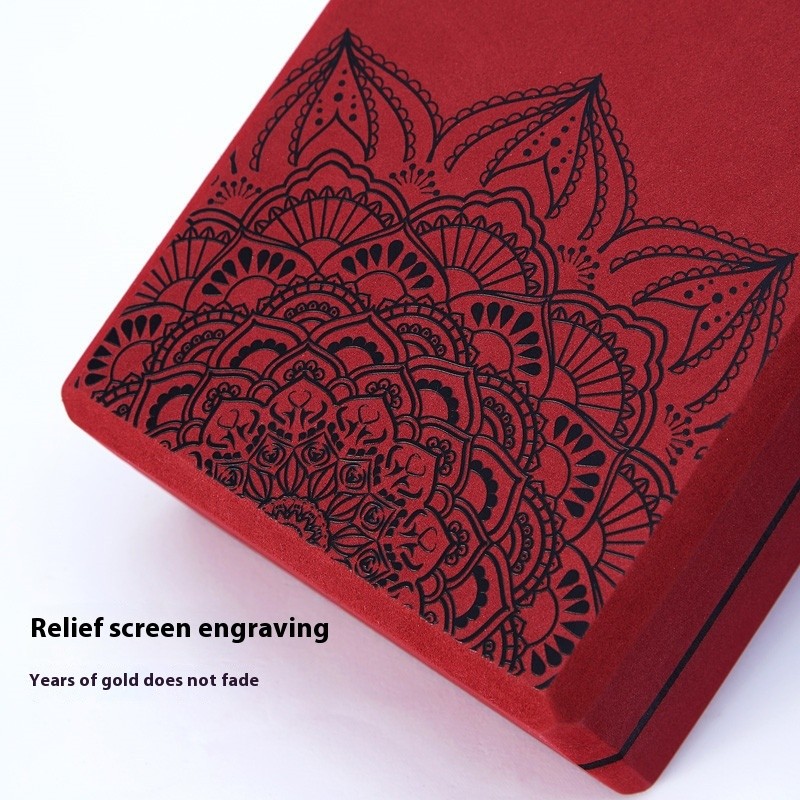

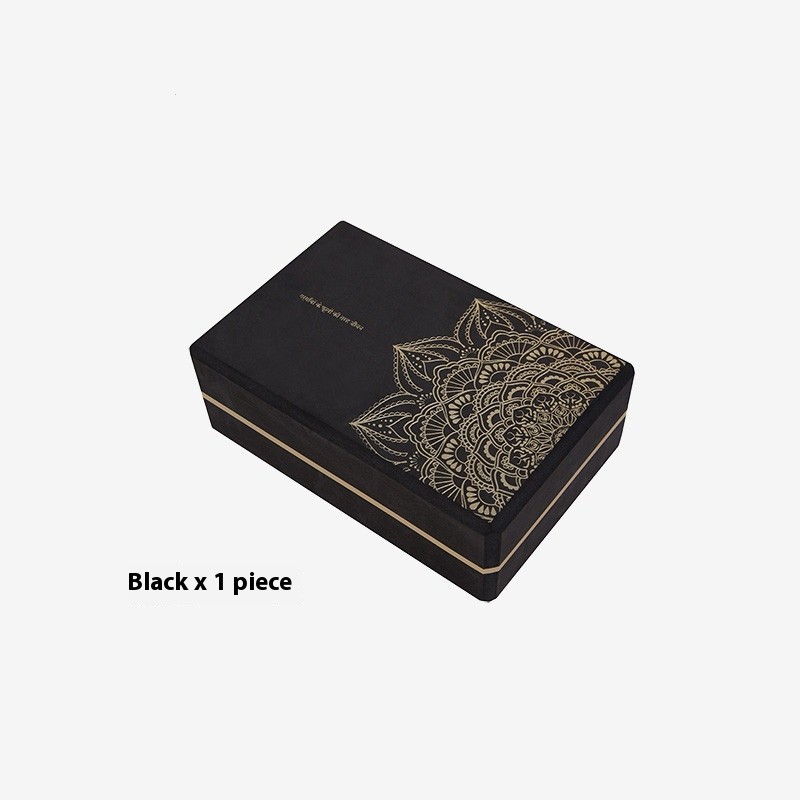

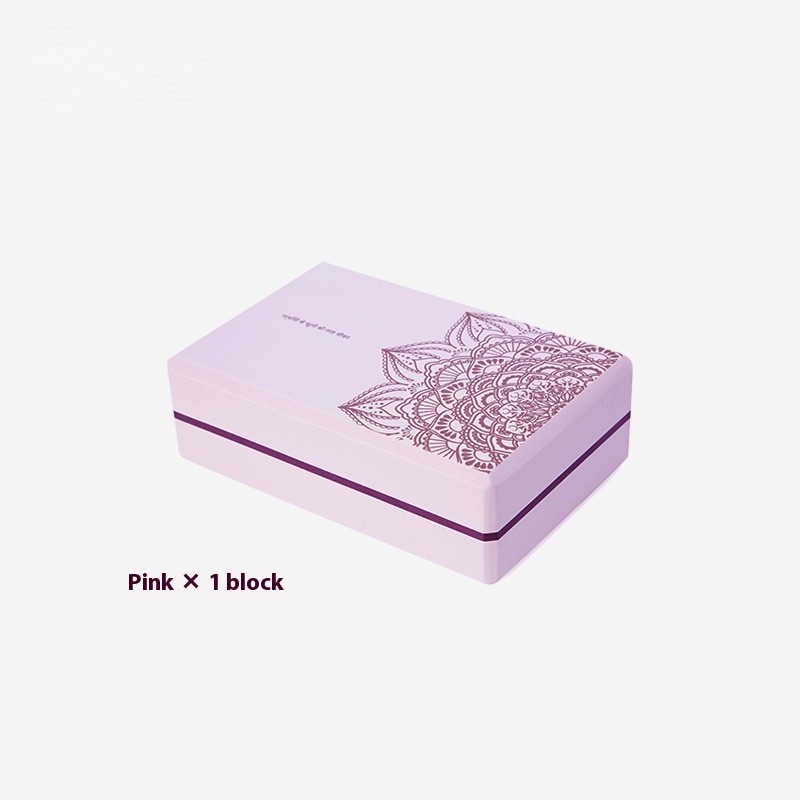

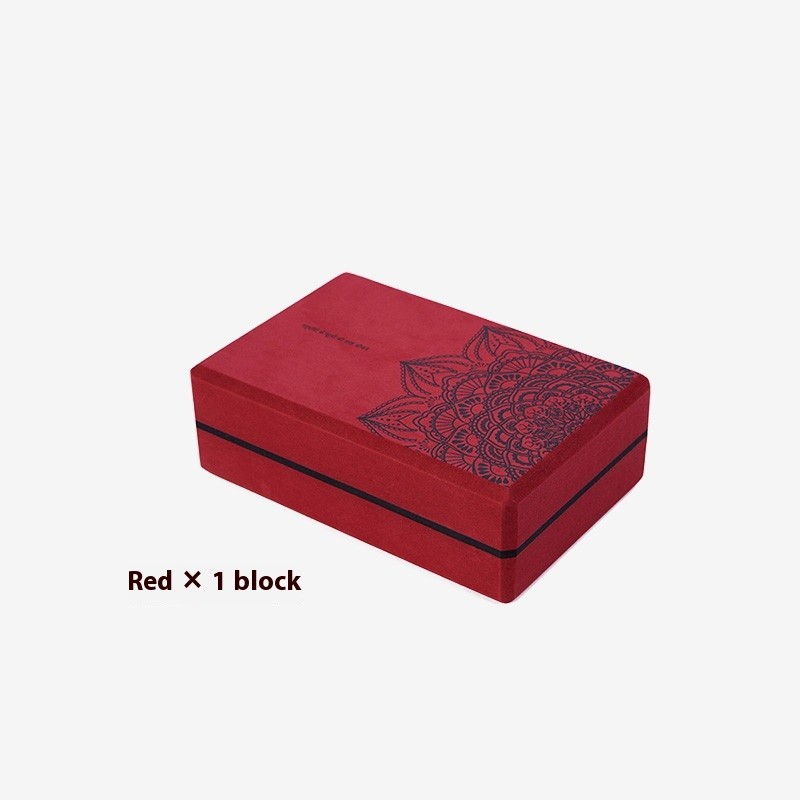

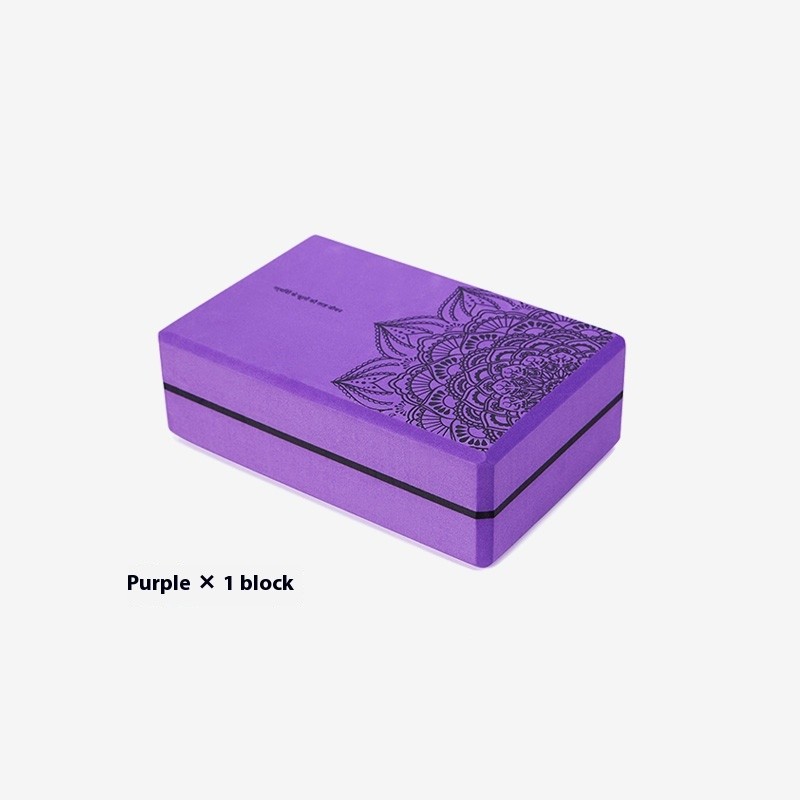

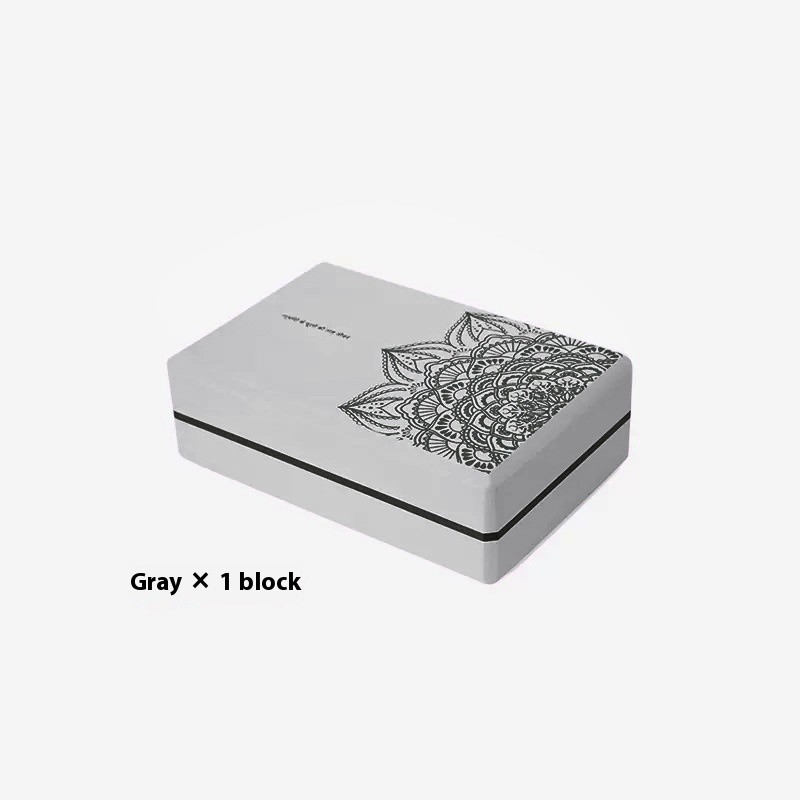

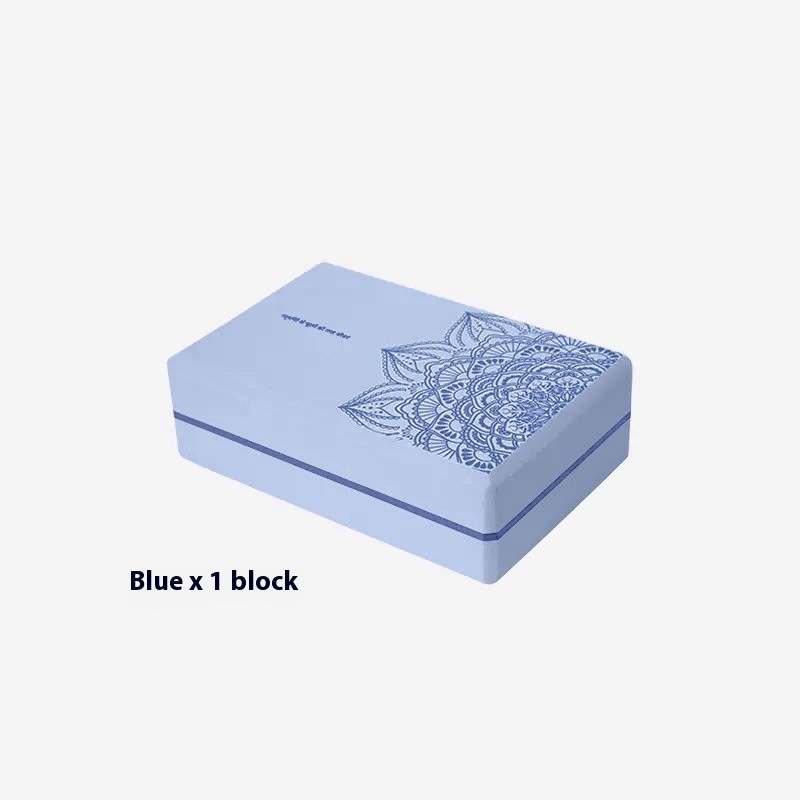

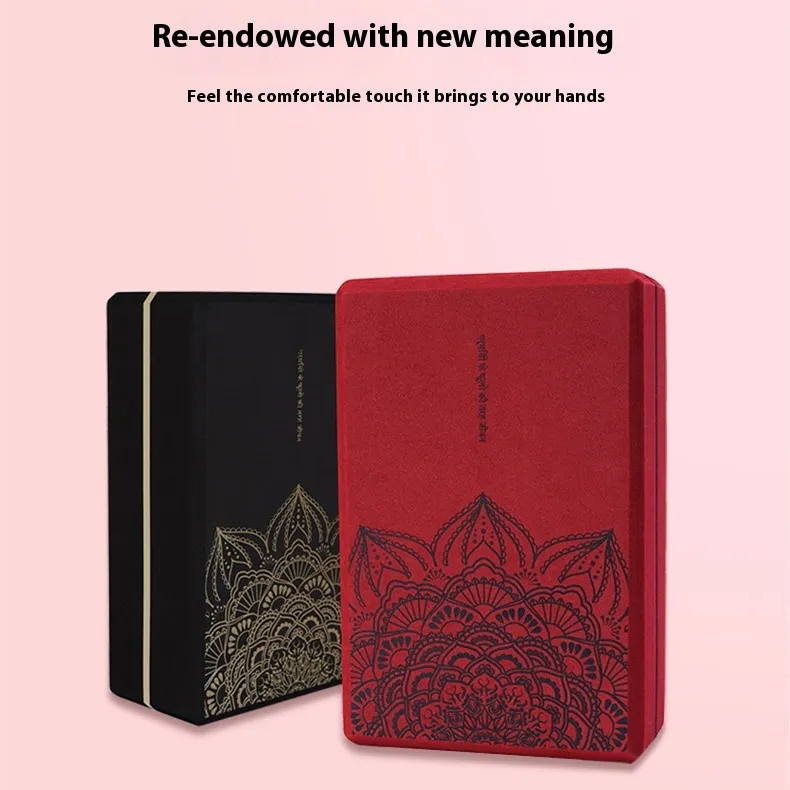

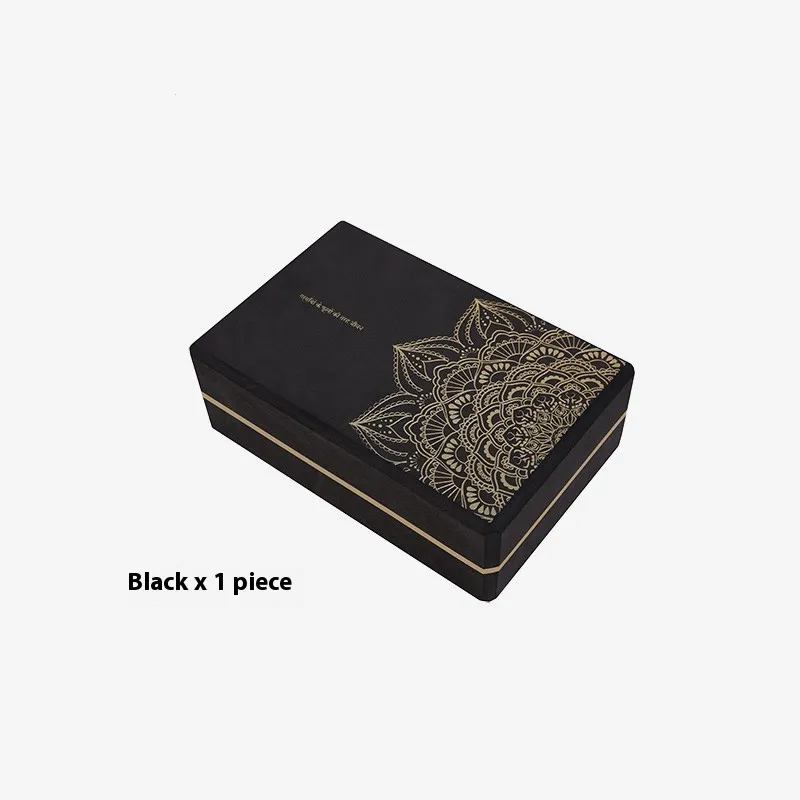

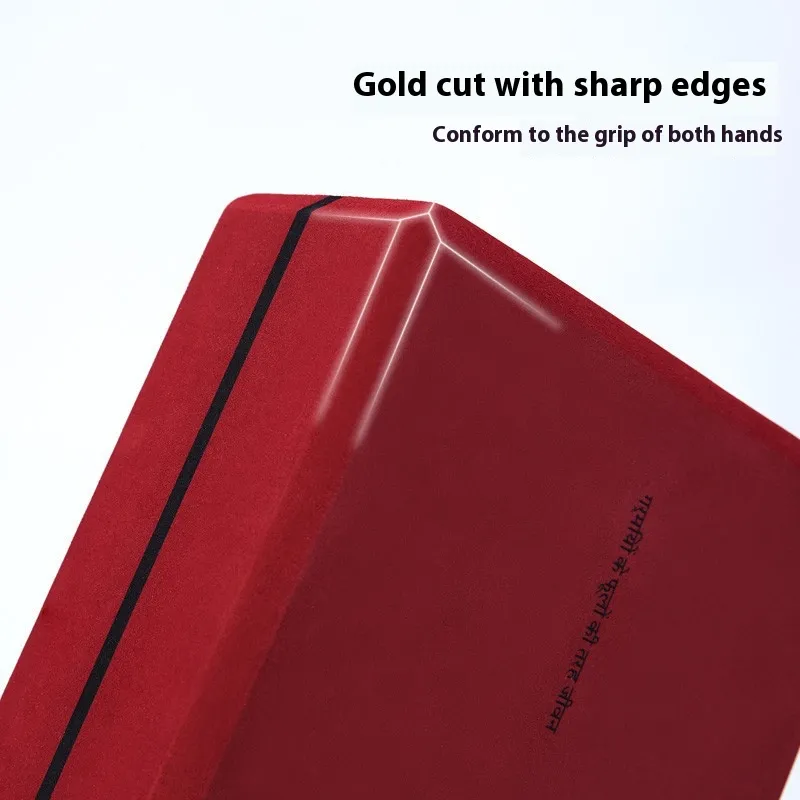

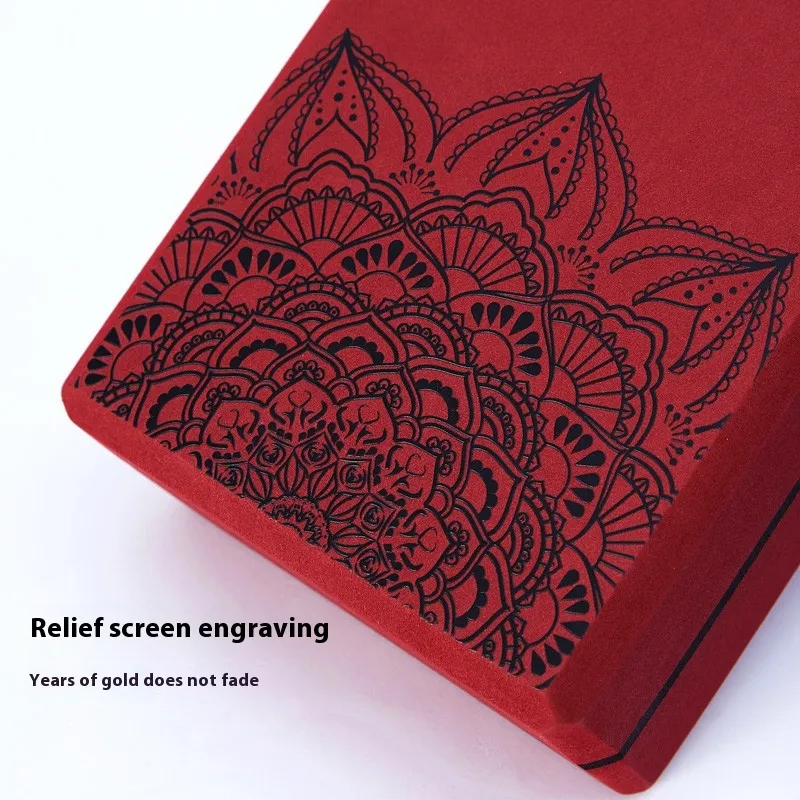

Pattern: datura flowers

Applicable scenarios: Fitness body, Dance Sports

Color: Black, Blue, Gray, Pink, Purple, Red

Category: Yoga auxiliary products

Material: Bracelet

Product size: 23*15*7.5CM

Packing list:

Yoga block *1

Product Image:

High Density EVA Foam – Durable, Versatile Foam Solution for Craft, Packaging, and Industrial Use

Perfect for DIY Enthusiasts, Makers, Packaging Professionals, and Industrial Applications

High Density EVA (Ethylene Vinyl Acetate) Foam is an exceptional material chosen by professionals and hobbyists alike for its remarkable combination of density, durability, resilience, and comfort. Whether you’re working on precision craft projects, building protective packaging, creating cosplay armor, designing sporting equipment, or assembling industrial gaskets, high density EVA foam delivers reliable performance that meets a wide array of creative and functional needs.

This product description explores how high density EVA foam works, why it’s trusted across so many sectors, what makes it stand out, and how you can maximise its potential in your projects. From its unique material properties to its broad range of applications and benefits, this in‑depth guide equips you with the knowledge to use high density EVA foam effectively — whether you are a beginner or an experienced maker.

Description – High Density EVA Foam

High Density EVA Foam is a closed‑cell foam manufactured from a copolymer of ethylene and vinyl acetate. It’s known for its excellent balance of strength, flexibility, shock absorption, and resistance to water, chemicals, UV, and impact. The “high density” specification refers to its elevated mass per unit volume compared to standard EVA foam, which results in a firmer, more robust foam with enhanced load‑bearing capacity and durability.

The manufacturing process of EVA foam involves creating a cross‑linked molecular structure that traps gas bubbles, giving the foam its characteristic closed‑cell composition. This structure prevents liquids and air from penetrating, making it an ideal material for waterproof and impact‑resistant applications. High density EVA foam is typically supplied in sheets, rolls, or pre‑formed blocks with thicknesses ranging from a few millimetres to several centimetres, and it may be cut, shaped, glued, thermoformed, or layered depending on the end use.

Craft makers value high density EVA foam for its easy machinability, clean cut edges, and ability to accept surface painting or coatings. Packaging professionals utilise its shock absorption and cushioning properties to secure delicate items during transport. In sports and fitness gear, EVA foam is used in insoles, pads, mats, and protective gear where energy absorption, comfort, and durability are priorities. Industrial sectors incorporate high density EVA foam into seals, gaskets, noise dampening panels, and vibration‑control applications. Its versatility makes it a go‑to material wherever strength, weight savings, and comfort intersect.

Beyond practical functionality, high density EVA foam also excels in creative applications. Cosplayers and prop builders exploit its firmness and ease of shaping to fabricate lightweight costume armour, helmets, props, and artistic elements. Its surface readily accepts primers, paints, and finishes, enabling professional‑level customisation without compromising structural integrity. For makers and designers who want a material that bridges craft and industrial performance, high density EVA foam stands out as a reliable and adaptable choice.

This description outlines the technical nature of high density EVA foam while also highlighting its broad appeal due to performance consistency, ease of use, and aesthetic adaptability. Whether you need a foam that can withstand repeated compression, isolate vibration, cushion fragile goods, or become part of a visually striking design, this material delivers.

Key Points

-

High Density Composition

Contains a higher mass per unit volume than standard EVA foam, giving it enhanced firmness, structural integrity, and load‑bearing capacity.

-

Closed‑Cell Structure

Prevents water absorption, resists chemical penetration, and ensures moisture doesn’t compromise the foam’s performance or longevity.

-

Durable and Resilient

Exhibits strong resistance to wear, tearing, compression, and impact — ideal for protective padding, tooling, and heavy‑duty applications.

-

Excellent Shock Absorption

The foam’s molecular structure absorbs and disperses energy efficiently, making it perfect for protective gear, packaging, and cushioning.

-

Lightweight Yet Strong

Maintains a favourable strength‑to‑weight ratio that delivers functional performance without adding unnecessary weight.

-

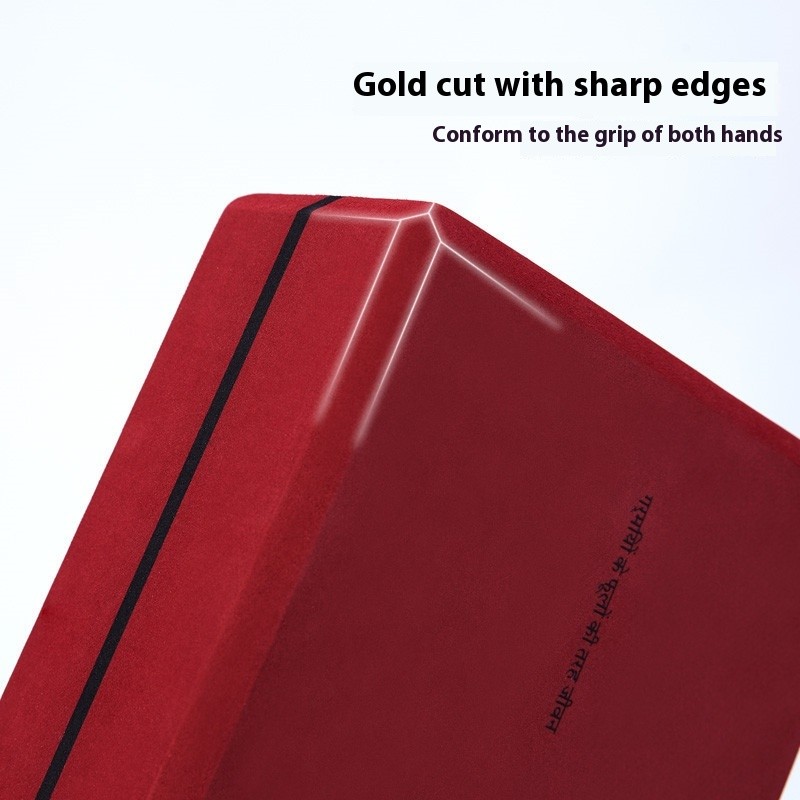

Cutting and Shaping Ease

Easily cut, carved, sanded, or thermoformed with standard tools, allowing precision shapes and trims in craft and industrial projects.

-

Surface Customisation Friendly

Accepts paints, primers, adhesives, and surface coatings, enabling creative finishes and custom designs.

-

Wide Range of Thicknesses and Sizes

Available in multiple sheet thicknesses (2 mm–50 mm+), roll options, and precut shapes for specific project needs.

-

Thermoformable Options

Can be heated and shaped into contours for ergonomic fitting, cosplay pieces, moulded inserts, or curved parts.

-

Resistance to UV and Aging

With appropriate formulation, high density EVA resists degradation from sunlight and ageing, preserving colour and performance over time.

-

Comfort and Grip

Offers a comfortable, slightly springy feel that works well for grips, mats, insoles, and ergonomic padding.

-

Wide Application Compatibility

Used in crafts, cosplay, automotive, sports equipment, packaging, gaskets, acoustic panels, and industrial seals.

-

Eco‑friendly Formulations Available

Many manufacturers produce EVA foam with reduced environmental impact, low VOC emissions, and recyclable options.

Benefits

1. Exceptional Durability

High density EVA foam is significantly more resistant to wear and compression than lower density alternatives. This durability means that products made with this material retain their shape and performance over extended use — whether it’s a workshop mat, protective padding, or industrial seal.

2. Superior Shock and Impact Absorption

Its ability to absorb and disperse energy makes high density EVA foam ideal for protective applications: sports pads, helmets, footwear insoles, packaging inserts, and cases for fragile equipment all benefit from the foam’s capacity to reduce peak impact forces.

3. Waterproof and Moisture‑Resistant

Because of its closed‑cell structure, the foam repels water and resists moisture ingress. This makes it perfect for outdoor applications, marine environments, shower mats, and any scenario where water exposure is expected.

4. Easy Machining and Shaping

Unlike some foams that crumble or tear, high density EVA foam cuts cleanly with knives, hot wire cutters, or CNC tools. This allows for precision work in crafts, model making, packaging inserts, automotive components, and cosplay builds.

5. Comfortable and Supportive

The foam offers a balance of firmness and slight springiness, which provides comfortable support in wearable applications (e.g., insoles or padding) without feeling hard or rigid. It’s also effective in ergonomic contexts where long‑term contact occurs.

6. Temperature Sensitivity and Thermoformability

High density EVA foam can be heated and shaped to form contours, curves, and ergonomic forms — a valuable property for custom projects requiring complex geometry and snug fits.

7. Aesthetic and Design Flexibility

Its smooth surface takes coatings, paints, primers, and adhesives well, allowing creative customisation without compromising material integrity. This makes it excellent for themed craft projects, decorative elements, and high‑end prototype models.

8. Environmentally Friendly Options

Many manufacturers offer formulations with reduced VOCs (volatile organic compounds), recyclable foam variations, and production processes with improved environmental performance — ideal for eco‑conscious designers and businesses.

9. Cost‑Effective Performance

Compared to solid plastics or specialised engineering materials, high density EVA foam delivers premium performance at a lower cost, making it a practical choice for prototypes, custom projects, and large‑volume applications.

10. Versatile Across Industries and Use Cases

From industrial gasketing to children’s craft projects, from cosplay armour to protective floor tiles, the broad adaptability of high density EVA foam means one material can serve countless needs — reducing inventory complexity and broadening creative potential.

11. Strong Bonding with Adhesives

When using contact cement, hot glue, or specialised foam adhesives, high density EVA foam bonds reliably without delamination, allowing layered assemblies, laminated skins, and complex builds.

12. Consistent and Predictable Performance

Engineered with consistent cell structure and density standards, high density EVA foam delivers repeatable properties that designers, engineers, and creators can trust for quality results.

13. Safe and Non‑Toxic Formulations

When produced with certified standards and tested for safety, high density EVA foam is non‑toxic, latex‑free, and safe for consumer applications — including toys, mats, and wearable products.

14. Vibrant Visual and Tactile Experience

The material can be supplied in various colours and finishes, providing aesthetic options without needing additional coatings or painting — useful for design projects that value both form and function.

15. Excellent Noise and Vibration Dampening

High density EVA foam can reduce noise and vibration when used in acoustic panels or equipment mounts, enhancing comfort in living spaces, vehicles, or machinery installations.

Why Choose This High Density EVA Foam?

Choosing High Density EVA Foam means selecting a material that bridges creative potential with industrial performance. Unlike low‑density foam that compresses easily and fails under moderate load, high density EVA foam offers permanent resilience, strength, and versatile adaptability. Whether you need a solution that stands up to daily wear, repeated compression, or demanding environmental conditions, this foam delivers without sacrificing workability.

For makers and creatives, its easy machinability and surface customisation unlock boundless design possibilities. For engineers and industrial designers, its predictable mechanical properties and moisture resistance ensure reliable performance in functional applications. The foam’s tight closed cells resist air and liquid ingress, making it suitable for both indoor and outdoor use. Its comfortable feel and ergonomic potential expand its usefulness into consumer products where human contact and support matter.

Comparatively, high density EVA foam outperforms many alternative materials like craft foam, neoprene, or low density polyethylene in load‑bearing, impact absorption, and durability while remaining cost‑efficient and easy to handle. Its broad compatibility with adhesives, coatings, and thermal forming processes means you can tailor projects without complex tooling.

Ultimately, this foam is chosen when projects demand strength, comfort, moisture resistance, and creative flexibility — all in one material that’s been proven across applications from sports gear to industrial gasketing.

Conclusion

High Density EVA Foam is a high‑performance, versatile, and cost‑effective material that meets the needs of professionals and hobbyists alike. Its exceptional balance of endurance, flexibility, and ease of use makes it a gold standard in foam materials — suitable for protective padding, ergonomic supports, packaging solutions, artistic creations, cosplay crafts, industrial seals, and beyond.

With its waterproof closed‑cell construction, superior impact absorption, and reliable bonding characteristics, this foam becomes more than a raw material — it becomes a foundation for creative expression, engineered solutions, and practical designs. Whether you are cutting intricate shapes for design prototypes, building rugged flooring systems, or creating functional ergonomic components, high density EVA foam supports your vision with strength and adaptability.

Choose high density EVA foam for projects that demand reliability, comfort, durability, and versatility — and unlock new possibilities for innovation and creativity in your work.

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

Shop amazing plants at The Node – a top destination for plant lovers

.png)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

ulva-Logo.jpg)

.jpeg)

.png)

.png)