Glass Cutting Tools NZ

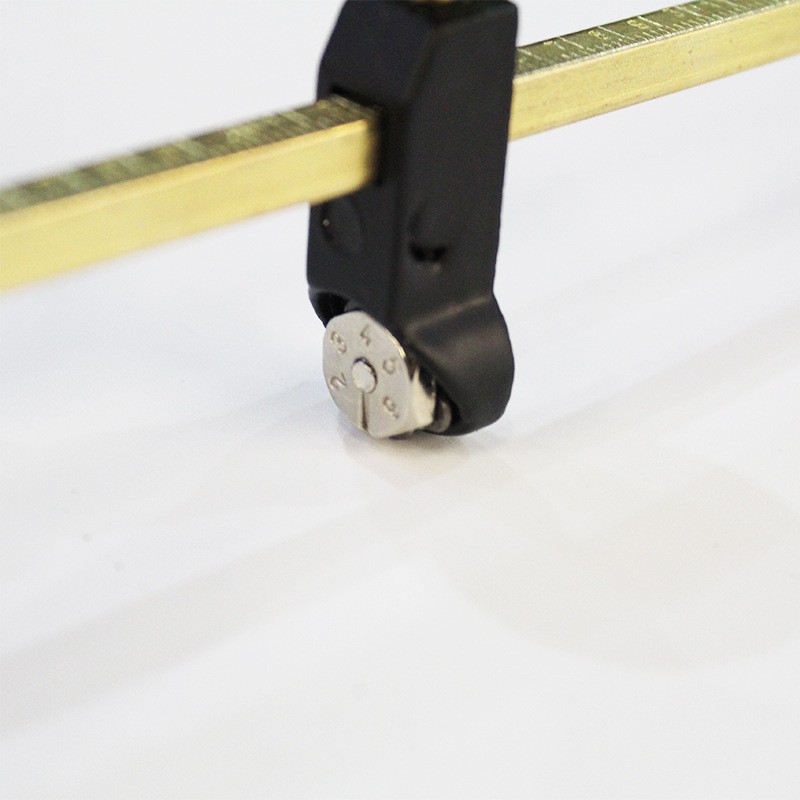

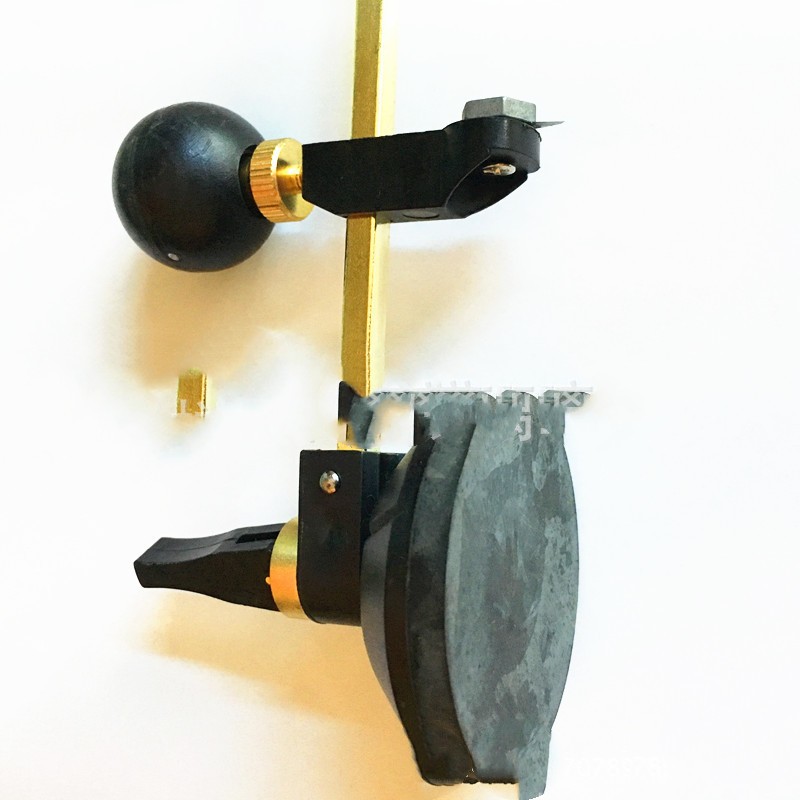

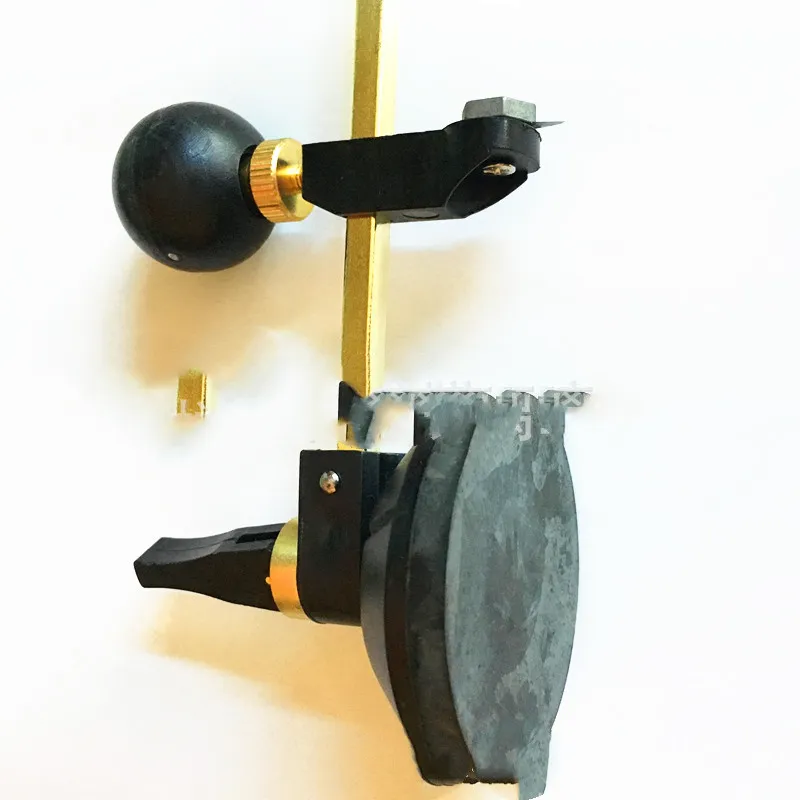

Model: compass cutter 0.4m-1.5m

Production process: Diamond

Bond: metal alloy

Glass Cutting Tools NZ – Cut with Precision, Control, and Confidence

Perfect for New Zealand Glaziers, Builders, DIYers, Craftspeople, and Renovators

The Glass Cutting Tools NZ are ideal for anyone in New Zealand who needs accurate, reliable tools for scoring, cutting, shaping, or trimming glass — whether you’re installing windows, repairing mirrors, cutting glass for craft projects, or preparing panes for renovation and build tasks. Designed for both professional use and home workshop application, these tools deliver clean cuts, consistent scoring, and improved control so that glass edges finish smoothly without cracking or break shards. With the right cutting tool and accessories, you can tackle a wide range of glass types — from standard window glass to plate glass, picture glass, stained glass or tempered glass preparation (where applicable).

Description – Glass Cutting Tools NZ

Glass Cutting Tools NZ encompass a complete range of devices and accessories used to score and break glass with precision and safety. These products include handheld glass cutters, tungsten‑steel cutters, oil‑fed roller cutters, pistol‑grip cutters, cutting pliers, suction lifters, straight edges, cutting mats, and specialised wheels. Each tool plays a role in creating clean score lines and enabling controlled separation of glass pieces along these lines.

A glass cutter typically consists of a hardened cutting wheel (often tungsten carbide or diamond‑tipped) mounted in a handle designed for ergonomic grip and steady pressure application. When run along a straightedge against the glass surface, the wheel creates a shallow score that weakens the surface tension. Controlled pressure then causes the glass to break cleanly along the scored line using nibblers, pliers, or simple hand support techniques.

Quality cutting tools are constructed from durable materials that hold their edge through multiple cuts, resist wear from glass abrasion, and provide consistent score depth. Some models include built‑in oil reservoirs that lubricate the cutting wheel to reduce wear and improve cut quality. Accessories such as cutting guides, squares and templates enable accurate layout and repeatability for repetitive cuts.

These glass cutting tools are essential in workshops, renovation projects, glazing installations, craft studios and anywhere precise glass handling improves results and safety. In NZ, where DIY home improvement is popular and construction codes demand quality finishes, these tools provide control and confidence for both novice and expert users alike.

Key Points

High‑Quality Cutting Wheels

Tungsten carbide or diamond‑tipped wheels provide clean, consistent score lines that improve break accuracy and reduce jagged edges.

Ergonomic & Stable Handles

Comfortable, non‑slip grips increase control and reduce hand fatigue during precision cutting tasks.

Oil‑Fed & Lubricated Cutting Options

Built‑in oil reservoirs and lubricated wheels reduce friction, extend wheel life, and enhance scoring smoothness.

Guides & Straightedge Accessories

Precision guides, squares and templates help align cuts accurately for repeatable, straight results.

Glass Breaking & Finishing Tools

Cutters are complemented by pliers, breaking tools and edge grinders that help separate, trim and smooth edges after scoring.

Benefits

Clean, Accurate Cuts Every Time

High‑quality scoring produces straight, reliable lines that make breaking predictable and clean — reducing breakage waste.

Versatile for Multiple Glass Types

Suitable for a range of glass thicknesses and formats — from window and picture glass to craft and panel work.

Improved Workshop Safety

Controlled cutting reduces shards and uncontrolled breaks, lowering the risk of cuts and injury.

Cost‑Efficient DIY Solution

Professional performance at a price point accessible to hobbyists and tradespeople alike, eliminating costly outsourcing of cuts.

Enhances Project Quality

Better cut quality means improved fitment, smoother edges, and more polished final installations or craft pieces.

Why Choose These Glass Cutting Tools NZ?

Choosing Glass Cutting Tools NZ means selecting a lineup engineered for precision and reliability tailored to Australasian glass materials and common workshop conditions. Unlike basic or cheap scoring tools that wear quickly or produce inconsistent cuts, these tools use refined cutting wheels and ergonomic designs that hold up under repetitive use in professional or DIY applications. With diverse tool options — from simple handheld cutters to advanced guided systems — you can match tool choice to task complexity and skill level.

Oil‑fed models increase lifespan and reduce resistance during scoring, while diamond‑tipped wheels maintain sharpness for longer runs. Guides and templates improve accuracy across repeated cuts, meaning fewer mistakes, less waste, and cleaner edges. Quality finishing tools help refine cut edges for safety and presentation, ensuring your glass projects look professional and perform as intended.

Whether you’re glazing windows, crafting custom glass panels, repairing damaged panes or experimenting with glass art, these tools give you control, accuracy and confidence — turning glass cutting from a challenging task into a manageable process.

Expanded Discussion of Core Features

High‑Quality Cutting Wheels

The cutting wheel is the heart of any glass cutter. Tungsten‑carbide wheels offer a balance of hardness and durability suited for routine scoring tasks, while diamond‑tipped wheels handle more abrasive or thicker materials with ease. Wheel diameter and profile influence score depth — preference often depends on glass thickness and user technique. Quality cutters ensure consistent wheel engagement and scoring depth, critical for predictable break lines.

Ergonomic & Stable Handles

A stable grip reduces the risk of slipping during scoring. Ergonomic handles improve comfort and control, especially over extended use. Non‑slip materials such as textured rubber or ergonomic shapes help steadier pressure application — a significant factor for cleaner cuts and fewer mistakes.

Oil‑Fed Cutting Systems

Certain cutters include an internal oil reservoir that delivers lubrication to the cutting wheel during scoring. This reduces friction, prolongs wheel life, and creates smoother score lines by preventing heat buildup and glass surface scoring resistance. These systems are especially beneficial for frequent or extended cutting tasks.

Guides & Straightedge Accessories

Accessories like T‑bars, adjustable squares and precision guides help users keep score lines straight and exact — vital for panels, craft pieces, window replacements, shelving or decorative glass applications. Pairing a guide with a cutter improves accuracy and repeatability, especially for long, continuous cuts.

Glass Breaking & Finishing Tools

After scoring, controlled breaking is essential. Breaking tools such as running pliers or groziers help separate pieces along the score line with minimal force and reduced risk of unintended breakage. Edge grinders, sanding stones or finishing kits smooth cut edges to eliminate sharpness and prepare the glass for installation.

Practical Use Cases

Window Glass Cutting & Installation

Cut glass to precise dimensions for window replacements, repairs or custom installations — ensuring neat fits and improved energy efficiency.

Mirror & Picture Frame Preparation

Trim mirror panes or picture glass to size for custom frame projects or decorative installations.

Craft & Art Projects

Artists and hobbyists can score and shape glass pieces for mosaics, stained‑glass work, panels, terrariums, or light fixtures.

Glass Shelving & Panel Work

Create custom glass shelving, cabinet inserts or protective panels that fit exactly in your built‑in units or furniture.

Trade & Workshop Use

Professional glaziers and tradespeople benefit from reliable tools that support repeat performance in workshops, on‑sites, and fabrication tasks.

Maintenance & Care

To keep your Glass Cutting Tools NZ in peak condition, regularly clean scoring wheels and guides to remove dust and glass debris. Replace worn cutting wheels as they dull to maintain score quality. For oil‑fed models, maintain appropriate lubricant levels and flush reservoirs periodically to avoid buildup. Store tools in a dry, organised toolbox to prevent corrosion and protect delicate edges on guides and finishing accessories. Inspect breaking pliers and grinding stones for wear and replace worn parts to preserve performance and safety.

Conclusion

Glass Cutting Tools NZ provide New Zealand glaziers, tradespeople, DIYers and craft enthusiasts with the precision, durability and control required for high‑quality glass cutting and finishing tasks. With robust cutting wheels, ergonomic designs, guided accessories and reliable breaking tools, these products convert glass cutting into an accurate, efficient process — reducing waste, improving safety, and boosting overall project quality. Whether you’re fitting windows, crafting decorative panes, or preparing glass for architectural features, these tools deliver the performance and confidence needed to achieve professional results.

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

Shop amazing plants at The Node – a top destination for plant lovers

.png)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

ulva-Logo.jpg)

.jpeg)

.png)

.png)