Dust Collector NZ

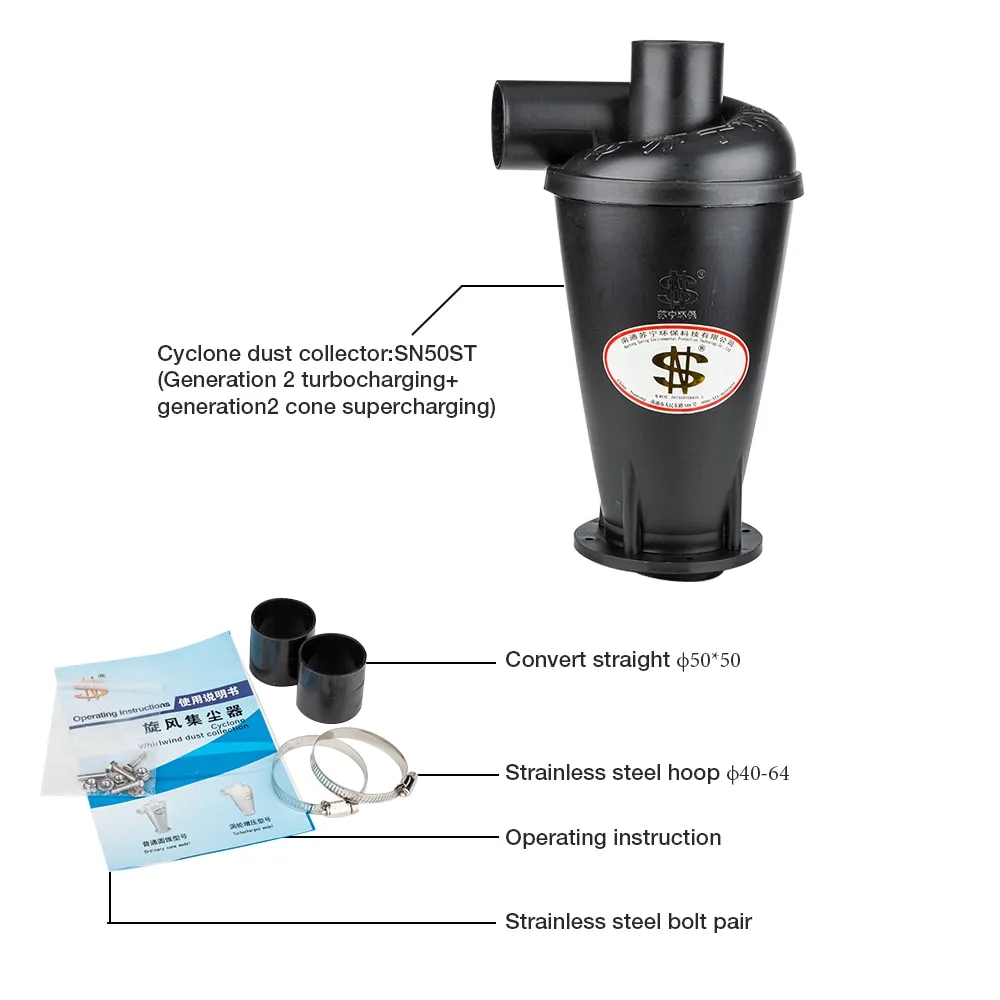

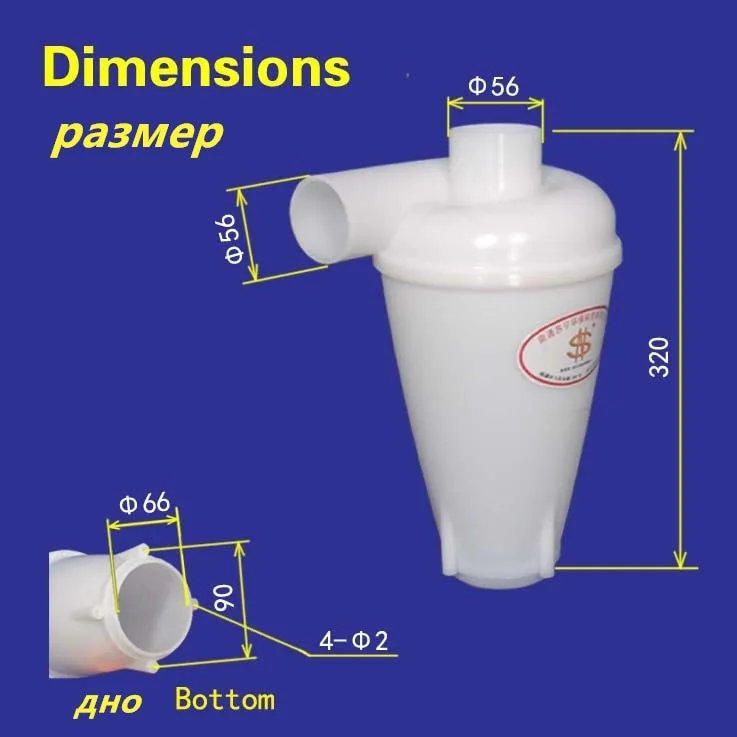

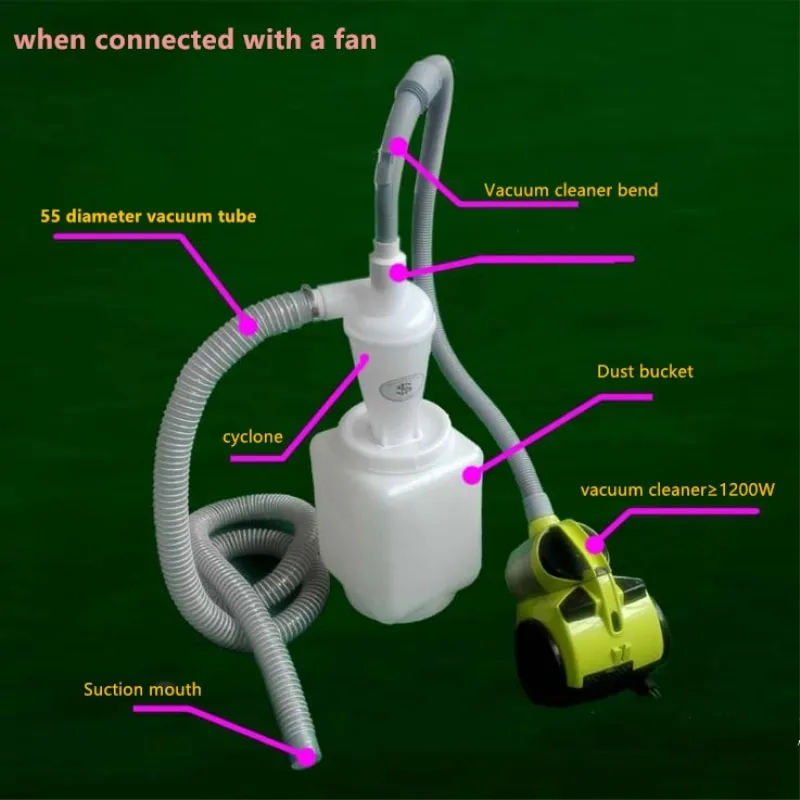

size:190*165*320mm

Features:

- dust collection

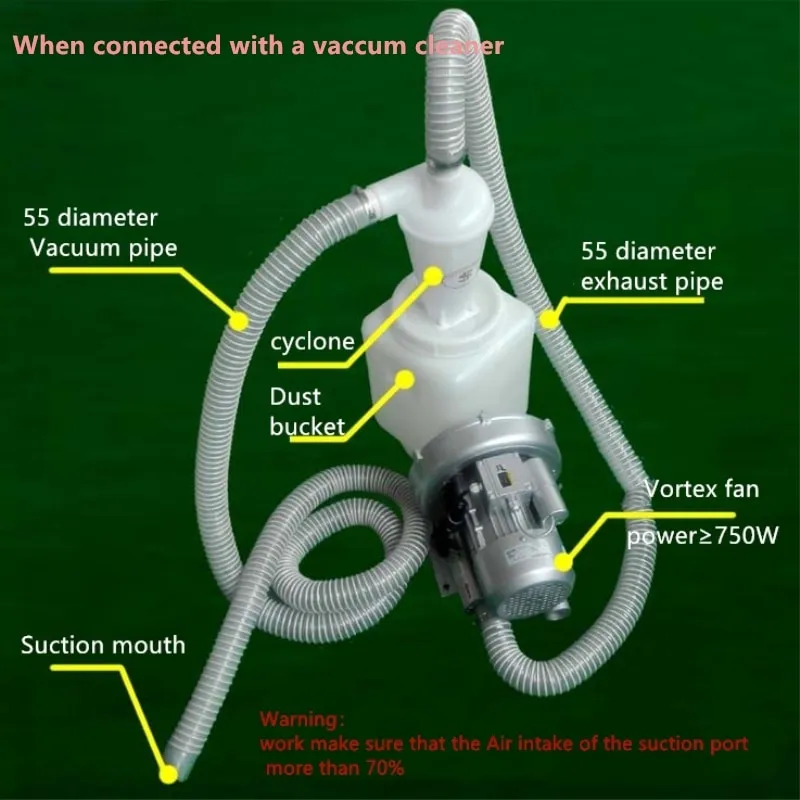

Is a cyclone system - captures up to 99% of dust before reaching the shop vacuum

- injection molded from black antistatic hard plastic

- It is the ideal companion for vacuum cleaners for filtration/separation

Wood chips, flower chips, plastic and aluminum, etc.

Dust Collector NZ – Cleaner Air, Better Workshop Performance

Perfect for New Zealand Woodworkers, Metalworkers, Trade Workshops, Renovators, and DIY Enthusiasts

The Dust Collector NZ is ideal for anyone in New Zealand who works with power tools, woodworking machines, metal fabrication tools, sanding equipment or home renovation debris and needs an effective way to manage dust, chips, shavings and fine particulate. Whether you’re running a busy professional workshop, building cabinetry, crafting furniture, or improving your garage workspace, this dust collection system removes harmful dust at the source, improves air quality, enhances tool efficiency, and keeps work areas clean and safe.

Description – Dust Collector NZ

The Dust Collector NZ is a robust extraction system designed to capture and contain dust and debris generated during cutting, sanding, routing, drilling, grinding and other airborne particulate‑producing tasks. These systems typically consist of a powerful motor, impeller or blower assembly, filter housing, collection bag or bin, and inlet ports that connect to tools via flexible hoses or ductwork. By pulling dust away from the work surface and into a central containment unit, a dust collector reduces cleanup time, prolongs tool life, and improves health and safety conditions in workshops — particularly where fine wood or metal dust is prevalent.

Constructed with heavy‑duty materials such as steel or reinforced plastics, the unit supports frequent use in commercial and home workshop environments. Filter media — such as pleated cartridges, HEPA‑rated panels or multi‑stage bags — trap fine particles while allowing larger debris to settle in a separate chamber. Adjustable suction settings, caster wheels for portability, and multiple inlet ports help tailor operation to various machines and tasks. Models range from compact single‑stage units for small garages to powerful two‑stage systems suited to larger workshops, industrial applications and fleet environments across New Zealand.

Key Points

High‑Efficiency Dust Extraction

Powerful motor and impeller design maximise airflow to pull fine and coarse dust away from tools and into the collector.

Multi‑Stage Filtration

Filter systems such as cartridge filters, HEPA filters or bag systems trap fine dust while preventing blowback into the workspace.

Flexible Port Connection

Multiple hose inlets and connector options allow simultaneous connections to sanders, table saws, planers, routers and other equipment.

Portable & Durable Design

Sturdy construction with caster wheels or forklift pockets for ease of movement and long service life in NZ workshop environments.

Adjustable Suction Control

Variable power or gate controls let you tune suction for different tools and dust loads, reducing power use and improving efficiency.

Benefits

Improved Workshop Air Quality

Removes harmful dust and particles that can cause respiratory issues, skin irritation and long‑term health concerns.

Enhanced Tool Performance & Longevity

Dust‑free cutting surfaces and internal tool paths reduce wear, overheating, and maintenance needs.

Reduced Cleanup Time

Centralised collection significantly cuts down on sweeping and vacuuming, increasing productive working hours.

Safer Working Environment

Limits combustible dust accumulation — especially in woodworking and composite material applications — supporting safer workshop conditions.

Why Choose This Dust Collector NZ?

Choosing this Dust Collector NZ means investing in a system engineered for real‑world workshop demands in New Zealand. Unlike basic shop vacuums that struggle with fine particulate and continuous use, a dedicated dust collector features higher airflow capacity, industrial‑grade filtration and designed‑for‑purpose construction that stands up to heavy workloads.

Dust collectors remove debris at the source, reducing fine dust suspended in air — a significant advantage over sweep‑and‑vacuum routines that redistribute particulate. Professional models integrate with multiple machines simultaneously, making them indispensable for serious woodworking shops, metal fabrication facilities, and home carpentry spaces that run table saws, jointers, planers, sanders and routers.

With multi‑stage filtration and robust containment, these units minimise downtime, lower maintenance costs, and create cleaner, safer working conditions. Adjustable suction and porting options let users tailor extraction to tool power and dust load, improving efficiency and reducing wasted airflow. Whether you’re operating a commercial setup or elevating your DIY workshop, this dust collector supports better outcomes and enhances day‑to‑day workflow.

Expanded Discussion of Core Features

High‑Efficiency Dust Extraction

At its core, a dust collector uses a high‑capability motor and impeller or blower to create sufficient airflow (measured in cubic metres per hour, m³/h) to draw dust directly into the collection chamber. Unlike standard wet/dry vacuums, the design prevents motor overheating during continuous operation and delivers steady suction across multiple inlet connections.

Multi‑Stage Filtration

Modern dust collectors feature filter media engineered to trap varying particle sizes:

- Primary Collection Bag or Bin: Captures larger chips and wood shavings.

- Cartridge or Pleated Filter: Catches finer particles down to micron‑level.

-

HEPA/Secondary Filters: Optional high‑efficiency filters that trap ultra‑fine dust and support asthma‑friendly workshop

environments.

Effective filtration prevents particulate recirculation, maintaining air quality and keeping surfaces cleaner.

Flexible Port Connection

Dust collectors support multiple inlet ports and hose configurations to connect with stationary tools — like table saws, routers and jointers — or handheld tools via adaptors. This flexibility means one central unit can serve several workstations, reducing redundancy and maximizing power usage.

Portable & Durable Design

Many models include rugged steel or reinforced polymer cabinets and caster wheels that allow repositioning around busy workshops or job sites. Larger units may feature fork pockets or lift handles for transport on pallets or in vans. Durable construction ensures reliable performance in NZ conditions — including coastal, dusty or busy commercial spaces.

Practical Use Cases

Woodworking Shops

Connect to table saws, planers, sanders and routers to capture dust and chips at source — improving cut quality and reducing airborne debris.

Metal Fabrication

Extract lightweight metal dust and grinding residue to maintain stable working conditions and prevent surface contamination.

Home Workshops & Garages

Compact models offer powerful extraction for DIY woodworking, renovation debris capture and hobby fabrication without overtaking space.

Commercial Fabrication Facilities

High‑capacity systems handle multiple tools and high dust loads — ideal for factories, production floors and busy trade workshops.

CNC & Routing Stations

Capture fine particulate from CNC machines, routers and laser cutters, protecting machinery and reducing airborne contamination.

Maintenance & Care

To maintain your Dust Collector NZ, regularly empty collection bags or bins before they become overly full, as clogged chambers reduce airflow efficiency. Clean or replace filters periodically according to manufacturer guidance — spiked filter cleaning wipes, compressed air or reverse‑pulse systems help sustain performance. Inspect hoses, connections and seals for leaks or wear and replace damaged parts to preserve suction integrity. For units with HEPA filters, adhere to specified replacement schedules to ensure air quality standards remain effective.

Conclusion

The Dust Collector NZ is an indispensable tool for any New Zealand workshop, trade site, fabrication facility or DIY space needing clean, efficient dust extraction. With high‑capacity airflow, multi‑stage filtration, flexible porting and durable construction, it improves air quality, extends tool life, reduces cleanup time and enhances safety in demanding environments. Whether you’re working with wood, metal, composites or renovation debris, this system delivers powerful extraction, adaptable performance and long‑term reliability that supports both professional and hobbyist workflows.

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

Shop amazing plants at The Node – a top destination for plant lovers

.png)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

ulva-Logo.jpg)

.jpeg)

.png)

.png)