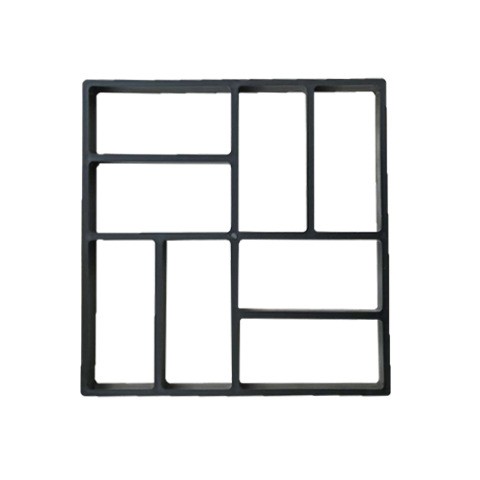

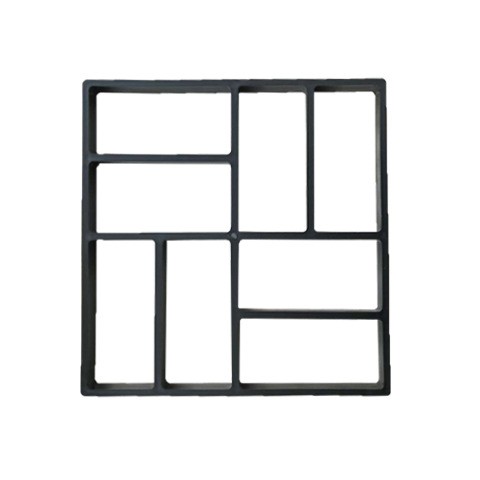

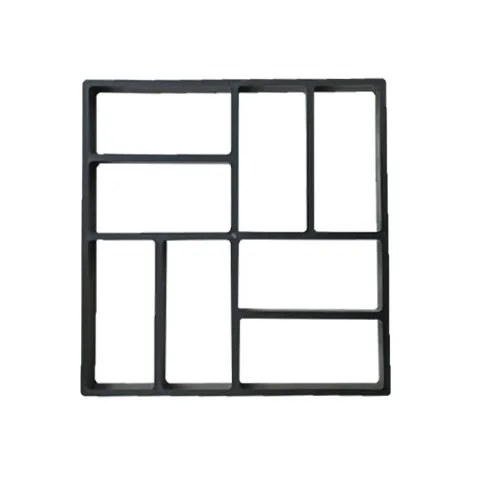

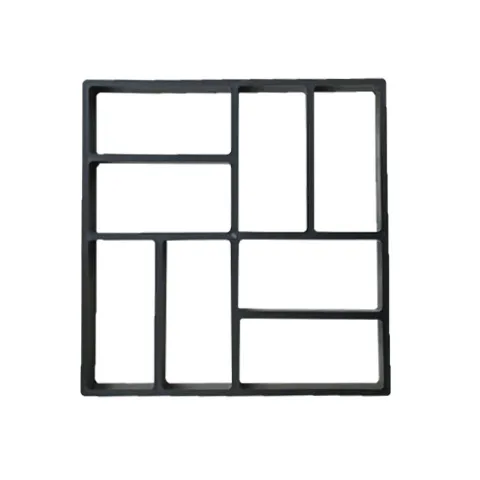

Concrete Molds

Product Information:

Name: Paving Mould

Item No.: LYDIY

Purpose: pavement

Size Information:

Specifications: 43*43*4cm, 50*50*4cm, 45*40*4cm, 45*45*4cm, 40*40*4cm, 40*40*4cm

Packing:

Paving mould X1

Concrete Molds – Shape Concrete with Precision & Creativity

Perfect for New Zealand Builders, DIYers, Landscapers, Gardeners, and Craftspeople

The Concrete Molds are ideal for anyone in New Zealand who needs reliable forms for shaping concrete into functional or decorative elements. Whether you’re a professional tradesperson creating steps, pavers, edging, or architectural details, a landscape designer crafting garden features, a DIY enthusiast making planters and outdoor furniture, or a hobbyist producing decorative ornaments, these molds deliver predictable results with minimal effort. With durable construction and thoughtful design, they help you produce consistent shapes, reduce waste, accelerate workflow, and enhance the quality of finished concrete products.

Concrete molds transform raw concrete mixes into structured shapes — from simple blocks and bricks to complex decorative elements — eliminating guesswork and repetitive fabrication tasks. Designed for NZ conditions, they balance durability, ease of use, and versatility, making them suitable for indoor projects, backyard builds, outdoor installations, and light commercial use. Whether shaping a pathway, creating custom stepping stones, forming structural components, or producing planter boxes, the right set of concrete molds empowers users to achieve professional‑grade results with confidence.

Description – Concrete Molds

Concrete Molds are purpose‑built formwork tools used to cast concrete into predefined shapes and sizes. They are typically made from durable materials such as rigid plastic, reinforced rubber, polypropylene, metal, or composite polymers that withstand repeated use and resist abrasion from concrete mixes and additives. Each mold provides a cavity that defines the outer geometry of the finished concrete piece, while also supporting the weight and hydrostatic pressure of wet concrete during setting.

Available in a broad range of formats — from interlocking paver molds, slab and tile molds, block forms, sphere and planter shapes, decorative patterns, block letter molds, and structural formwork — concrete molds simplify complex shaping operations. More advanced mold sets include flexible silicone or rubber liners that facilitate easier demoulding and finer surface details.

Using concrete molds typically involves preparing a concrete mix to the appropriate consistency, applying a release agent (if recommended), filling the mold cavity, vibrating or tapping to eliminate air pockets, allowing sufficient curing time, and finally removing the cast piece. Well‑designed molds include features to prevent sticking and facilitate smooth removal, such as tapered edges, non‑stick surface coatings, handles, and alignment guides.

Concrete molds support a wide range of project types — from pathways, patios, and retaining walls to garden ornaments, custom furniture, and decorative façade elements. Their repeatability enables consistent results and simplifies both one‑off and batch production tasks.

Key Points

Durable Mold Construction

Made from heavy‑duty plastics, reinforced rubber or composite materials that resist wear, cracking and degradation from concrete and

environmental exposure.

Versatile Shape Options

Molds are available for pavers, blocks, slabs, tiles, decorative elements, spheres, planters, edging, and more — supporting both functional

and aesthetic builds.

Easy Demoulding Design

Incorporates thoughtful features such as tapered walls, non‑stick surfaces, handles, and flexible edges to facilitate smoother demoulding

and reduce damage to casts.

Reusable & Repeatable

Engineered for multiple uses with consistent shape retention, allowing builders to produce multiple units with the same form factor without

degradation.

Scalable for Projects

Suitable for single‑piece creations and large batch runs, supporting both small backyard projects and larger landscaping or structural

tasks.

Benefits

Consistent Quality Output

Casts concrete shapes with uniform size and detail, reducing variation and improving finished surface quality compared to ad‑hoc forming

methods.

Time & Labour Savings

Eliminates manual shaping, cutting and finishing work required with freeform pours, accelerating production and reducing physical effort.

Creative & Customisable Designs

Supports a wide range of creative shapes — decorative stones, textured tiles, lettered blocks, geometric patterns — enhancing design

flexibility.

Durability & Longevity

High‑quality molds withstand repeated casting cycles, resisting wear and deformation, which maximises return on investment for frequent

users.

Improved Safety & Handling

Standardised forms remove guesswork from handling wet concrete, reducing mistakes and helping maintain safer workflows for novice and

experienced builders alike.

Why Choose These Concrete Molds?

Choosing these Concrete Molds means opting for a blend of robust design, reusable performance and practical versatility tailored to New Zealand build environments. Unlike fragile or poorly engineered alternatives that warp, crack or produce inconsistent casts, these molds are constructed to resist the abrasive and alkaline nature of concrete mixtures. Material choices — from reinforced thermoplastics to flexible rubbers — are selected for longevity and durability under repeated loading, curing cycles, and exposure to wet conditions.

The range of available shapes and sizes ensures compatibility with diverse project requirements — from garden paver production and patio tile fabrication to ornamental features and structural formwork. Molds are engineered with user‑friendly features that reduce the learning curve for beginners while offering precise control and repeatability for professional users. Non‑stick surfaces and integrated design elements expedite demoulding, thereby preserving sharp edges and fine details.

Using well‑designed concrete molds also enhances material utilisation — reducing waste, minimising patching work, and enabling more predictable material costing. For landscape projects, using consistent molds results in matched textures and patterns across pathways, walls and patios. For decorative applications, intricate molds capture fine surface details that elevate aesthetic impact.

Whether you are crafting in small batches or casting multiple units for large‑scale jobs, these concrete molds provide the reliability and versatility that elevate both functional and artistic builds.

Expanded Discussion of Core Features

Durable Mold Materials

The longevity of concrete molds hinges on the materials used in their construction. Heavy‑duty thermoplastics (such as high‑density polyethylene), reinforced polypropylene, composite polymers, and flexible silicone or rubber are common materials. These materials resist cracking, chipping and chemical attack from cementitious mixes. Rigid plastics maintain shape under concrete pressure, while flexible molds enable easier demoulding and more complex surface textures.

Extruded or injection‑moulded plastics resist abrasion and warping over repeated pours. Rubber and silicone variants provide elasticity that facilitates release, especially for intricate shapes or textured designs.

Shape Variety & Application Specificity

Concrete molds come in many configurations to support diverse tasks:

- Paver & Tile Molds: Create standard or decorative pavers and tiles for patios, driveways and walkways.

- Block & Brick Molds: Produce bricks, wall blocks and structural elements for masonry projects.

-

Decorative & Architectural Molds: Cast spheres, ornamental features, garden accents, columns, and façade details.

- Planter & Furniture Molds: Form integrated shapes for planters, stepping stones, benches, and tables.

- Edging & Curbs: Support garden edges, lawn borders, retaining edges and landscape details.

Each category serves specific design and functional purposes, enabling both practical and aesthetic concrete use.

Ease of Demoulding

Successful concrete casting requires removal of the finished piece without damage. Mold design elements such as tapered walls (draft angles), smooth inner surfaces, built‑in handling grips and non‑stick coatings or liners make this process efficient. Flexible molds expand or collapse slightly to release cured concrete, while rigid plastic molds rely on taper and surface finish to reduce adhesion.

Non‑stick agents or light releases (e.g., applicable oils) further reduce friction and help maintain surface quality.

Reusability & Scalability

High‑quality mold sets are engineered for repeated use. Durable materials and thoughtful design ensure that each casting cycle maintains shape integrity, enabling consistent scale production without loss of detail. This scalability is valuable for both batch production of pavers and individual specialized pieces.

Practical Use Cases

Pathway & Patio Paving

Create uniform pavers and tiles for garden paths, courtyards, patios and driveways. Molds support consistent sizing and patterning, enabling modular installations that interlock or align precisely.

Garden & Landscape Features

Produce decorative stepping stones, garden ornaments, planters, and edging elements that enhance outdoor aesthetics while maintaining durable, weather‑resistant construction.

Structural Blocks & Hardscape Walls

Use brick and block molds to cast masonry units for retaining walls, raised beds, seating walls and structural elements, ensuring dimensional accuracy and strength.

Custom Furniture & Outdoor Fixtures

Craft unique concrete benches, tables, stools and integrated landscape furniture pieces by casting forms that match design intentions.

Commercial & Public Spaces

Suppliers and builders can produce batches of tiles or forms for commercial courtyards, plazas, community spaces and institutional hardscapes with consistent quality.

Artistic & Decorative Projects

Molds with unique textures, patterns or lettered surfaces support artistic concrete applications — murals, signage bases, accent pieces, engraved faces and bespoke sculptural elements.

Step‑by‑Step Guide to Using Concrete Molds

-

Prepare the Mold: Clean the mold cavity and apply a release agent if recommended. Ensure all surfaces are dry and free from

debris.

-

Mix Concrete: Combine cement, aggregates and water per mix specifications suited to your task (flowable mixes for detailed

molds, stiffer mixes for structural forms).

-

Fill the Mold: Pour or trowel the concrete into the mold cavity, ensuring even distribution and avoiding air pockets.

-

Vibrate or Tap: Gently vibrate the filled mold or tap its sides to release trapped air and improve consolidation.

-

Strike Off: Level the top surface with a trowel or straightedge to remove excess and achieve a smooth finish.

-

Cure: Allow sufficient time for the concrete to cure — typically 24–48 hours for initial set and longer for full strength,

depending on mix and conditions.

-

Demould: Once cured, carefully release the form. Use flexible edges or tap the mold to separate the cast piece without

damage.

-

Finishing: If needed, perform light surface finishing — sanding, sealing, or texturing — before installation.

Maintenance & Care

To maximise the lifespan of your Concrete Molds, rinse them after each use to remove residual cement and prevent buildup. Avoid harsh abrasives that may scratch or degrade the mold surfaces. For flexible rubber or silicone molds, store them flat or supported to prevent permanent distortion. Rigid plastic molds should be stored away from direct sunlight and heat sources to prevent warping. Inspect molds periodically for cracks or wear that might affect casting accuracy and replace damaged units to maintain quality results.

Conclusion

Concrete Molds are indispensable tools for anyone involved in shaping concrete for practical or decorative applications. With a wide range of durable shape options, reusability, ease of demoulding and consistent output quality, they support everything from patio pavers and structural blocks to artistic elements and custom furniture. Designed for both professional and DIY use in New Zealand environments, these molds bring precision, efficiency and creative flexibility to concrete projects of all scales. By investing in quality mold sets, builders, artisans and homeowners alike empower themselves to produce polished, consistent concrete products that stand up to daily use and outdoor conditions.

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

Shop amazing plants at The Node – a top destination for plant lovers

.png)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

ulva-Logo.jpg)

.jpeg)

.png)

.png)