Compact Tubing Bender

Approx $24.70 USD

Features: ordinary

Material: aluminum alloy

Surface treatment: spray paint

Specification: metric system, English system

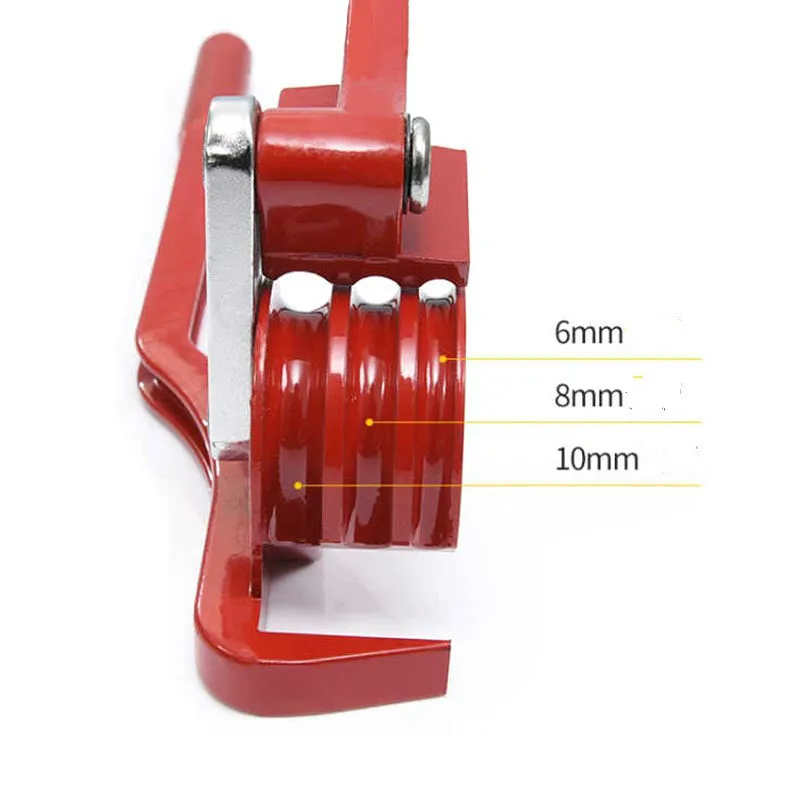

Product name: 180° metric three groove pipe bender

Product material: aluminum alloy

Supports: 0-180° elbow

Bendable: 6mm, 8mm, 10mm tube

Product Name: Compact Tubing Bender

H1: Compact Tubing Bender: Achieve Precise Bends with Ease and Efficiency

H2: Why Choose a Compact Tubing Bender?

A compact tubing bender is an essential tool for anyone working with pipes, tubes, or conduits, whether you’re a professional plumber, mechanic, or DIY enthusiast. Designed to easily bend various materials such as copper, aluminum, steel, and brass, this tool ensures that your tubes are shaped with precision and accuracy. Whether you’re working on a small home project or a larger commercial job, the compact tubing bender allows you to create clean, sharp bends without compromising the integrity of the material.

The compact design of these benders makes them easy to transport, store, and use in tight spaces, offering unparalleled convenience without sacrificing quality. Whether you’re working on automotive projects, HVAC installations, or plumbing systems, a compact tubing bender is a versatile, practical tool that helps you get the job done right every time.

H2: Key Features of a Compact Tubing Bender

H3: Lightweight and Portable

One of the standout features of a compact tubing bender is its lightweight design. These benders are engineered for portability, allowing you to easily carry the tool from job site to job site or store it in small spaces. The compact design ensures that you can use the bender in confined areas, making it ideal for a variety of projects, from vehicle repairs to plumbing tasks.

H3: Precision and Accuracy

Compact tubing benders are designed to provide accurate, clean bends every time. Whether you’re bending copper pipes for plumbing or metal tubing for automotive applications, the tool ensures that the tube is bent to the exact angle needed, without causing kinks or dents. The precision control allows for smooth and even bends, reducing the risk of material damage.

H3: Easy to Use

A compact tubing bender is simple to operate, making it accessible for both professionals and DIYers. Most models feature an ergonomic handle that provides leverage and ease of use, even when bending tough materials. The tool’s intuitive operation ensures that you can get the job done with minimal effort and without the need for specialized training.

H3: Durable Construction

These benders are built to last, with robust materials that withstand wear and tear. Made from high-strength steel or aluminum, compact tubing benders can handle bending tubes of varying thicknesses without losing functionality. Whether you’re working with soft copper or harder metals, the durable construction ensures that your bender remains reliable for years to come.

H3: Versatile Compatibility

Compact tubing benders are compatible with a wide range of tube sizes and materials. Whether you’re working with small-diameter copper tubing or larger aluminum pipes, the bender is designed to handle multiple sizes. Some models even come with interchangeable dies to accommodate different tube types and materials, making them a versatile tool for all types of jobs.

H2: Benefits of Using a Compact Tubing Bender

H3: Saves Time and Effort

Using a compact tubing bender streamlines the bending process, saving you time and effort compared to other methods, such as using manual force or relying on cumbersome machinery. The tool’s efficient design makes it easy to bend tubes quickly and precisely, ensuring you can move through projects faster without sacrificing quality.

H3: Reduces Material Waste

One of the biggest advantages of using a compact tubing bender is that it helps reduce material waste. By ensuring that your bends are accurate and clean, you avoid mistakes that could result in unusable or damaged tubing. This is especially important for expensive materials like copper and steel, where waste can lead to additional costs.

H3: Provides Consistent Results

Whether you’re making a few bends or a large number of identical bends, the compact tubing bender delivers consistent results every time. This is particularly beneficial when you need to ensure uniformity across multiple tubes in projects like piping systems, vehicle repairs, or HVAC installations.

H3: Ideal for Tight Spaces

Compact tubing benders are perfect for projects that require bending tubes in tight or confined spaces. The tool’s compact size and ability to operate in cramped environments make it ideal for work in vehicles, behind walls, or in small-scale applications where other, larger benders wouldn’t fit.

H3: Affordable and Accessible

For both DIY enthusiasts and professionals, compact tubing benders are an affordable solution compared to expensive hydraulic bender machines. These tools provide excellent value for money while offering the same precision and ease of use as more costly alternatives. Their affordability makes them accessible for homeowners and hobbyists who want to tackle small-to-medium bending tasks on their own.

H2: How to Use a Compact Tubing Bender

Using a compact tubing bender is straightforward and easy to master. Here’s a basic step-by-step guide on how to get started:

H3: Step 1: Set Up the Bender

First, make sure that your compact tubing bender is securely placed on a flat surface. Insert the tube into the bender’s die, making sure it’s aligned correctly. If your bender comes with interchangeable dies, select the appropriate die size for the tube you’re working with.

H3: Step 2: Position the Tube

Position the tube in the bender so that the portion you want to bend is inside the die. Ensure that the tube is fully inserted into the bender to avoid uneven bending or kinking.

H3: Step 3: Apply Pressure

Begin applying pressure to the handle of the bender. The ergonomic handle will give you the leverage needed to bend the tube smoothly. Continue applying pressure until the tube reaches the desired bend angle. Take care to monitor the bending process to avoid over-bending or damaging the tube.

H3: Step 4: Release and Check

Once the bend is complete, slowly release the pressure and remove the tube from the bender. Check the angle and ensure that the bend is smooth and free from kinks or dents. If necessary, make additional adjustments to achieve the perfect bend.

H3: Step 5: Clean and Store

After use, clean the bender to remove any debris or metal shavings that may have accumulated. Store the bender in a dry, cool place to protect it from rust or damage. Regular maintenance will ensure that your compact tubing bender lasts for years.

H2: How to Choose the Right Compact Tubing Bender

When selecting a compact tubing bender, consider the following factors to ensure you get the best tool for your needs:

H3: Material Compatibility

Ensure the bender is compatible with the material you intend to bend. Some benders are better suited for softer materials like copper or aluminum, while others can handle tougher metals like stainless steel. Choose a bender that fits the materials you work with most often.

H3: Tube Size Compatibility

Check the range of tube sizes that the bender can handle. Many compact tubing benders come with adjustable dies or multiple die sizes, allowing you to bend tubes of different diameters. Choose a bender that matches the size of the tubes you work with regularly.

H3: Ease of Use

Look for a bender that is easy to use and doesn’t require excessive force. Ergonomically designed handles and smooth action are essential for making clean, easy bends. If possible, try the bender before purchasing to ensure it feels comfortable and efficient to use.

H3: Durability and Build Quality

Opt for a bender made from high-quality materials that will last. Strong steel or aluminum construction ensures that the tool can handle heavy-duty use without breaking or losing its effectiveness. Look for benders with reinforced parts that can withstand frequent bending without warping or damage.

H2: Conclusion

A compact tubing bender is an essential tool for anyone who regularly works with tubing or pipes. Offering precision, convenience, and versatility, these benders allow you to achieve accurate bends with ease, making them ideal for automotive repairs, plumbing projects, HVAC installations, and more. With their durability, ease of use, and ability to work in tight spaces, compact tubing benders are an excellent investment for professionals and DIYers alike.

Invest in a compact tubing bender today to make your next project easier, faster, and more efficient!

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

Shop amazing plants at The Node – a top destination for plant lovers

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

ulva-Logo.jpg)

.jpeg)

.png)

.png)